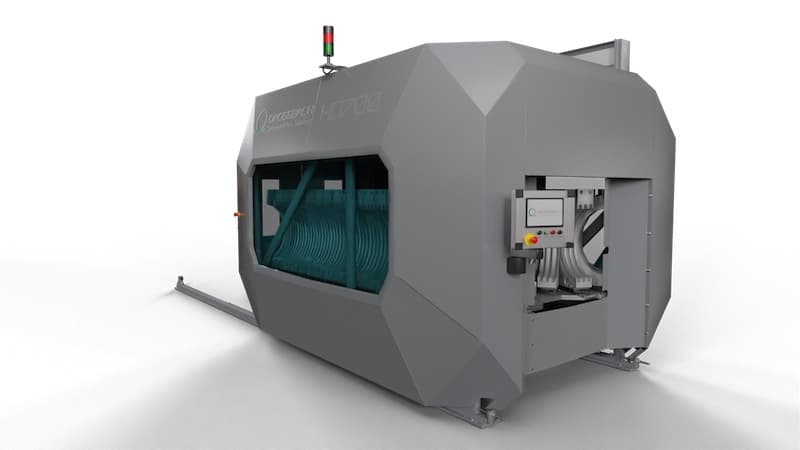

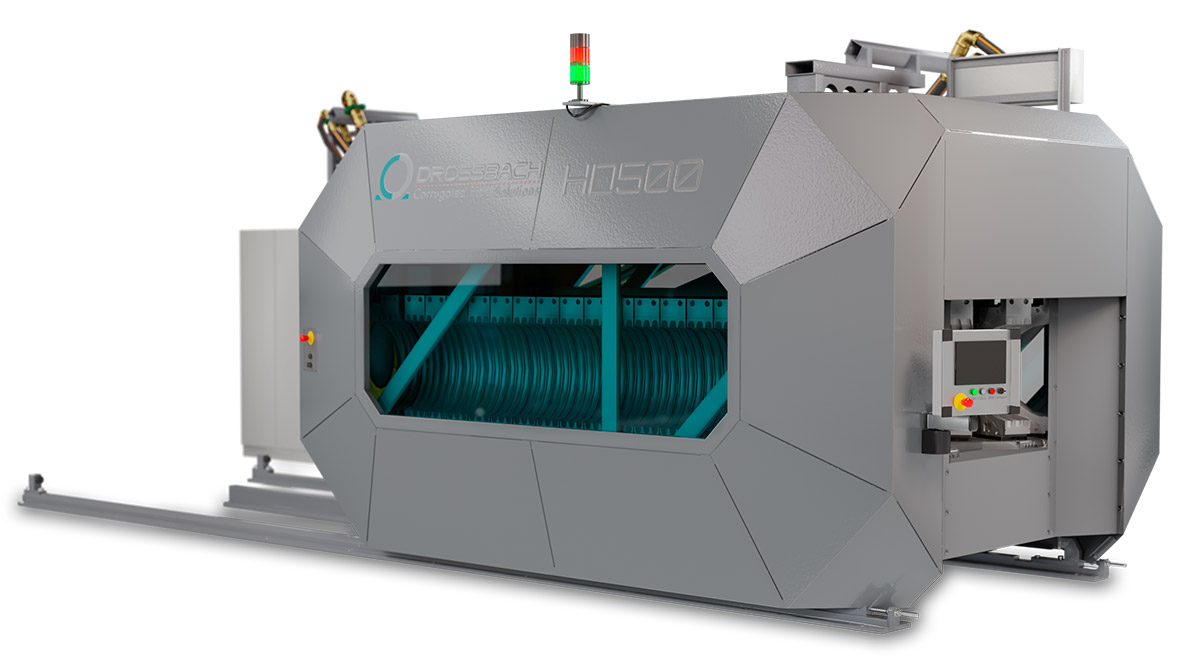

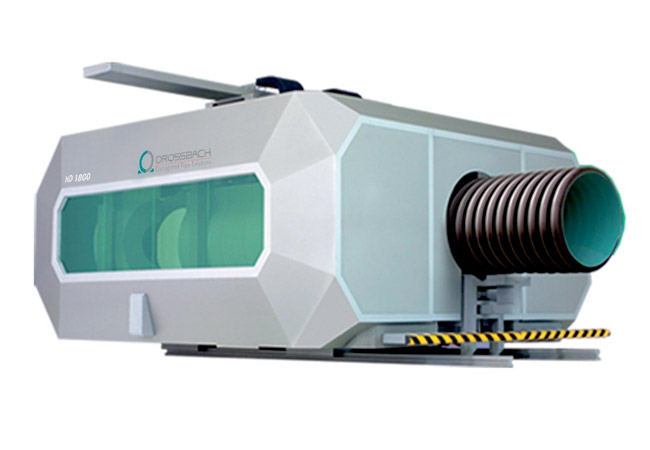

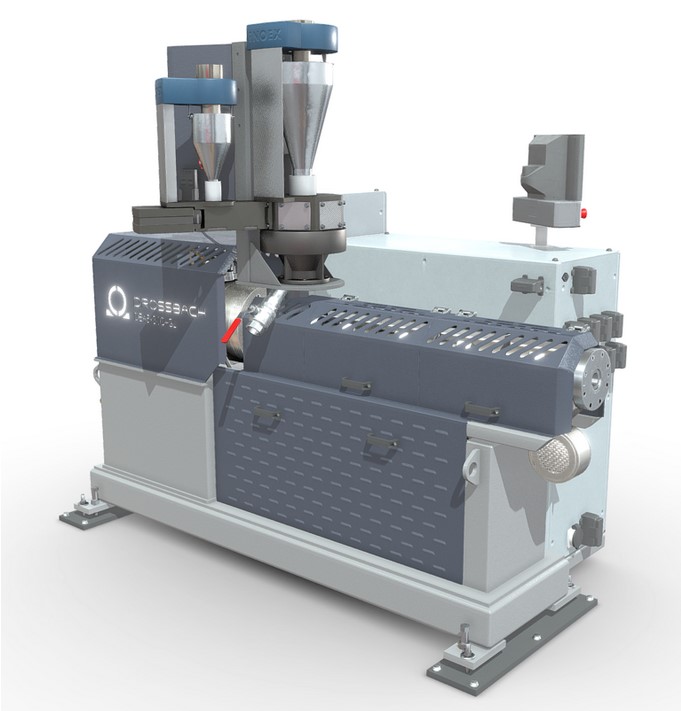

Drossbach HD 700

Superior performance for a wider diameter range.

Technical Data

| Max. mech. speed | 7,5 m/min |

| PE/PP output | 1050 kg/h |

| Measurement/weight: | |

| - Max. pipe outer diameter (OD) | 700 mm |

| - Min. pipe internal diameter (ID) | 150 mm |

| Number of mold blocks (per side) | 39 |

| Length | 5600 mm |

| Width | 4300 mm |

| Height (depending on extrusion height) | 3200 mm |

| Length of molding area | 2807 mm |

| Max. travel | 4000 mm |

| Weight of machine without mold blocks | 19500 kg |

Characteristics

Documentation

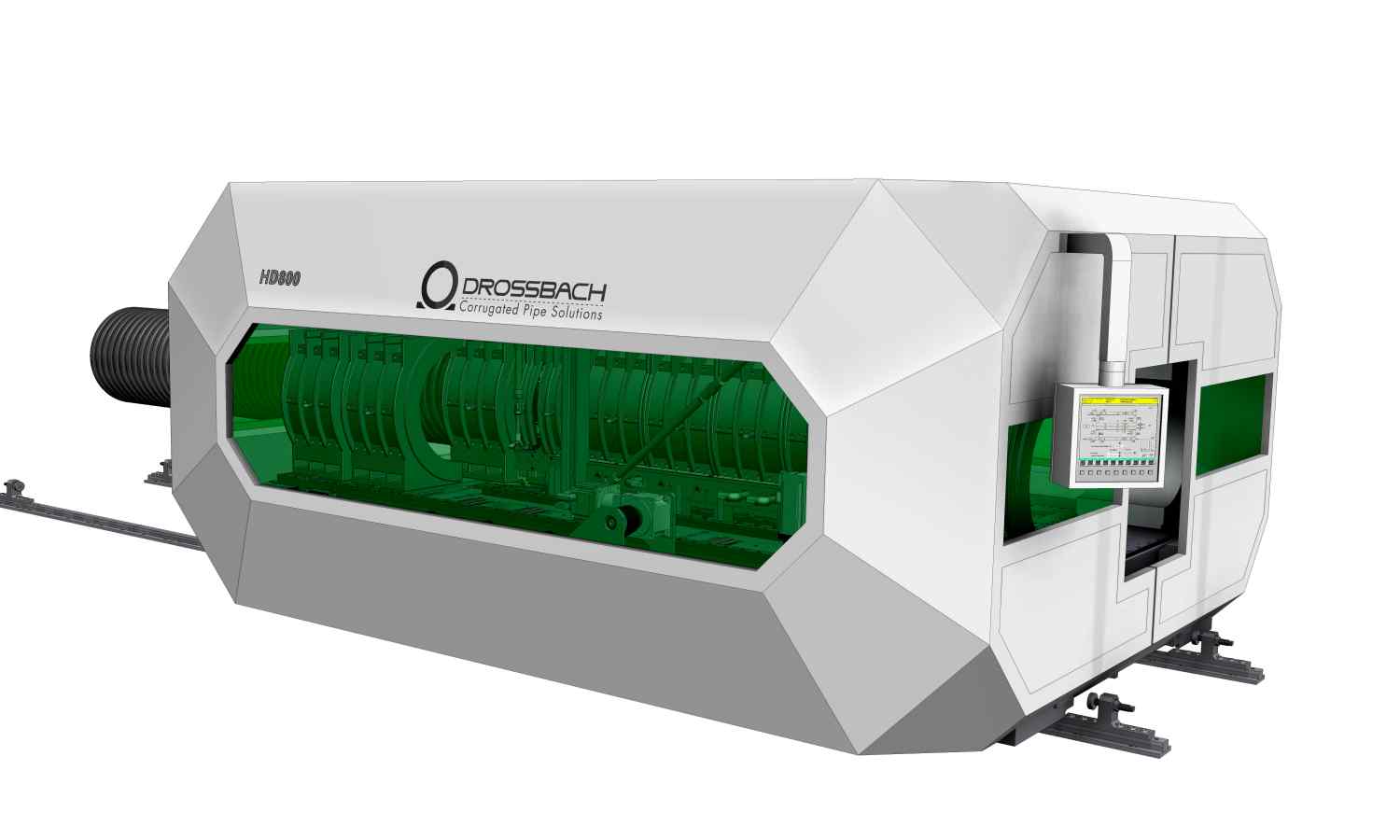

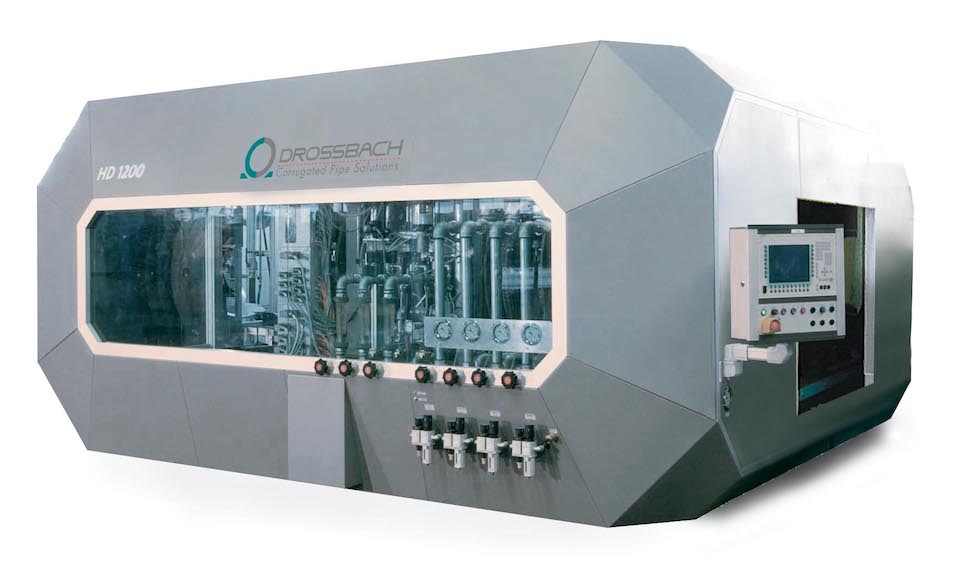

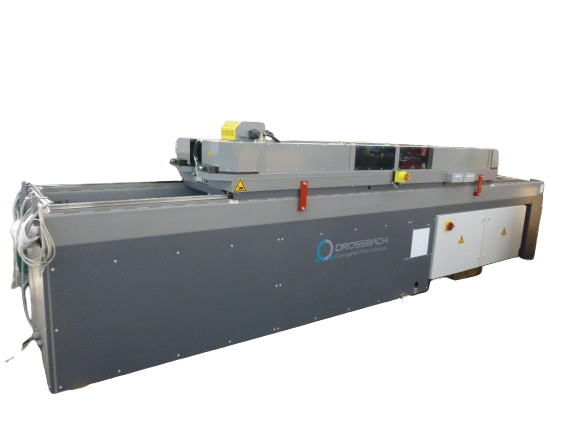

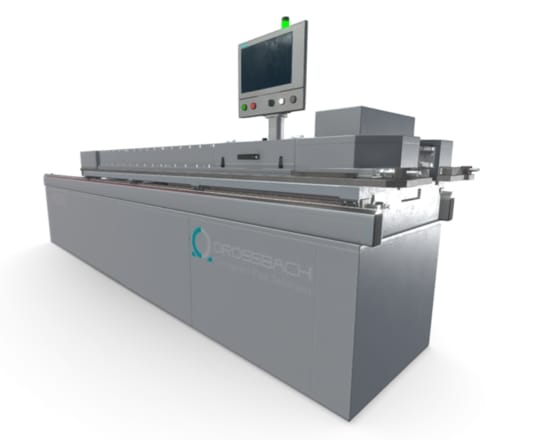

- Production of corrugated plastic pipes with high speed thanks to directly water-cooled mold blocks and an integrated full vacuum system.

- The corrugated pipe machine is mounted on a solid, welded frame. This guarantees stability during high-speed production.

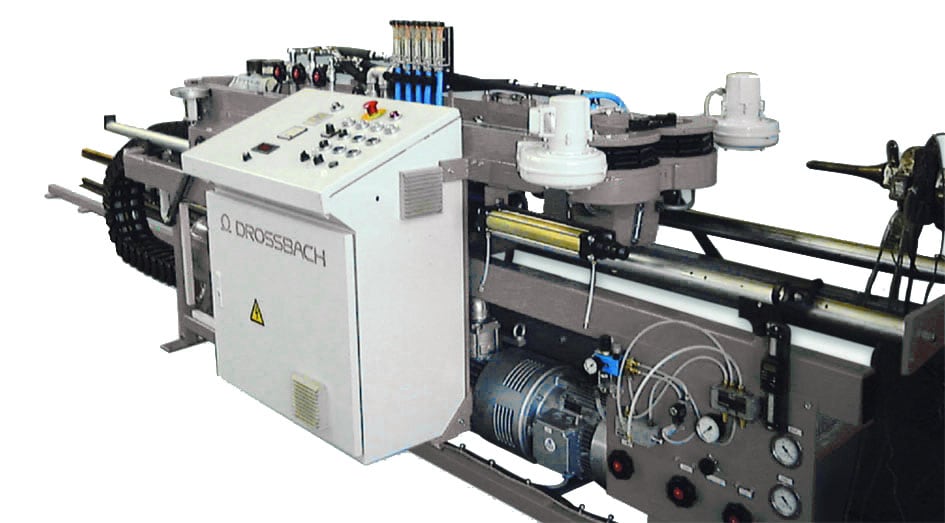

- Electrically driven side adjustment of the corrugator with position memory makes final tuning during production very simple and fast.

- Automatic vacuum control for perfect profiling of corrugated pipes. For each diameter and pipe material the necessary vacuum level is stored in PLC memory and selected on the operator’s panel.

- Equipped with 39 directly water-cooled mold block pairs to produce 6 m long pipes, if required including inline produced sockets.

- Mold blocks made of cast aluminum combine low weight and excellent heat transfer.

- The spiral-mandrel die head provides constant premium quality of the corrugated pipe with a consistent even wall distribution.

- After being adjusted, the die head is fixed to the corrugator by means of the centering ring, hence no further alignment necessary.

- Easy and convenient access to mold blocks due to special doors on both sides of the corrugator and pneumatically openable roof allowing use of an in-house crane for fast installation and removal procedures.

- Maintenance-free operation thanks a to fully automatic centralized lubrication system.

- The corrugator is equipped with State-of-the-Art drive system – no calibration needed during life-time operations.

- Simple and fast exchange of mold block inserts.

- The complete diameter tools from ID 150 to ID 400 are compatible with the HD 500 and the HD 1200.

DIAMETERS:

From ID 150 mm to OD 700 mm / 4” – 28”

Materials:

PE, PP, PVC, PA, PVDF, further plastics available upon request.

Superior performance for a wider diameter range.

Application

Waste water

ID 150 – OD 700 / 4” – 28”

Drainage

ID 150 – OD 700 / 4” – 28”

Rain water

ID 150 – OD 700 / 4” – 28”

Tunnel-shaped drainage type C1

ID 150 – OD 700 / 4” – 28”

Corrugators

Other equipment in this category

Create an order request

+