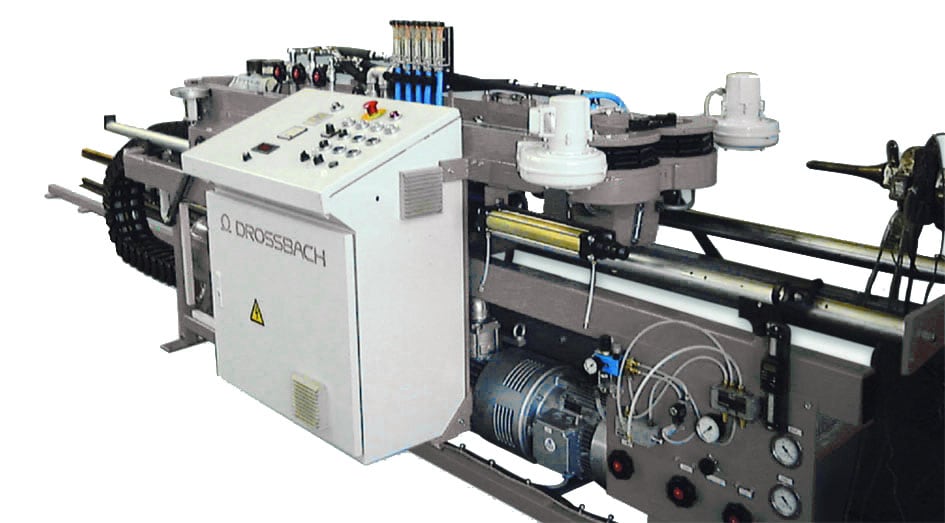

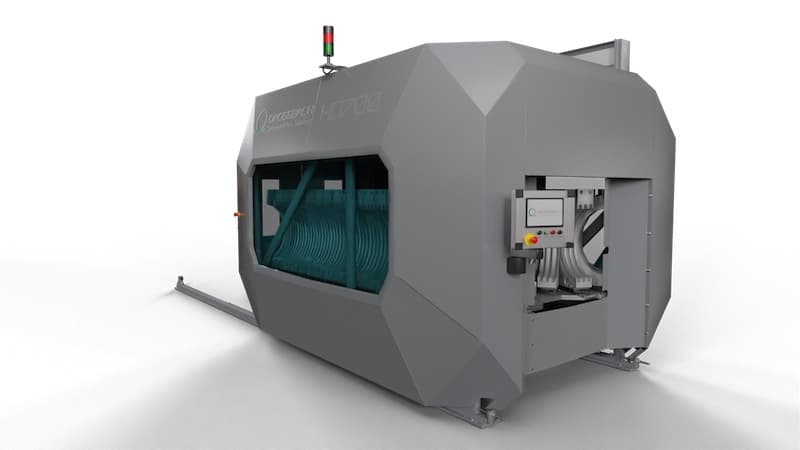

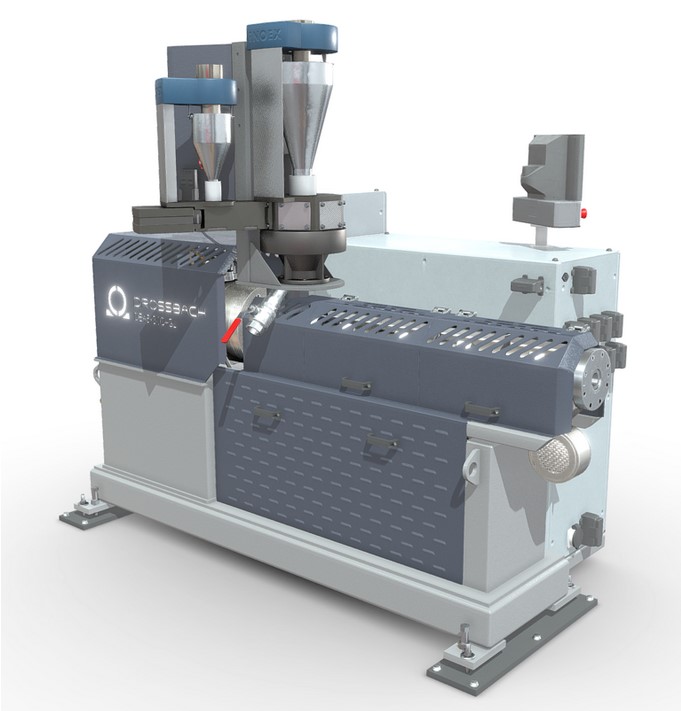

Perfect solution for production of corrugated pipes, smooth pipes, profiles, etc. Perfect companion for DROSSBACH corrugators as main extruder or co-extruder.

-

Screw and feeding bush design optimized for any specific customer’ needs

-

Wide range of processed thermoplastic materials

-

Bi-metallic wear resistant execution of screw and barrel for long life run

-

Thermo-insulated barrel – up to 20% energy saving

-

Grooved water-cooled feeding bush for higher output and stable melt pressure

-

Effective material processing guarantees perfect mixing, homogenous melt temperature and no unmolten particles

-

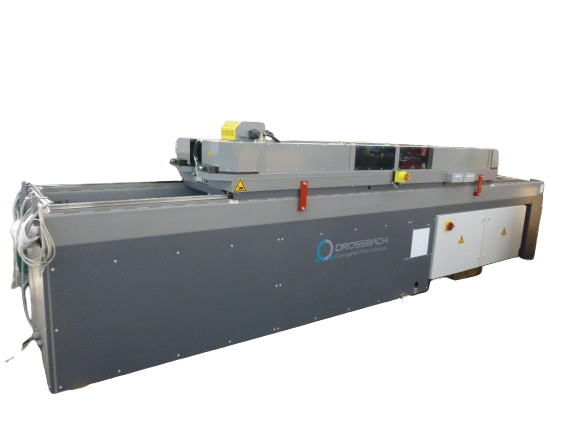

Gravimetric dosing system up to 6 components:

-

output & weight-per-meter automatic control

-

significant material saving due to minimum tolerances automatic mode

-

recipe storage and management

-

graphic display of technological parameters

-

real time monitoring of power consumption (kW*h, kW*h/kg)

-

alarm and diagnostic messages display

-

archiving and further access to production history

-

remote start-stop of downstream equipmen

-

Supported communication protocols: ProfiNet, CanOpen, Analog

-

Built-in webserver for remote diagnostics and monitoring

-

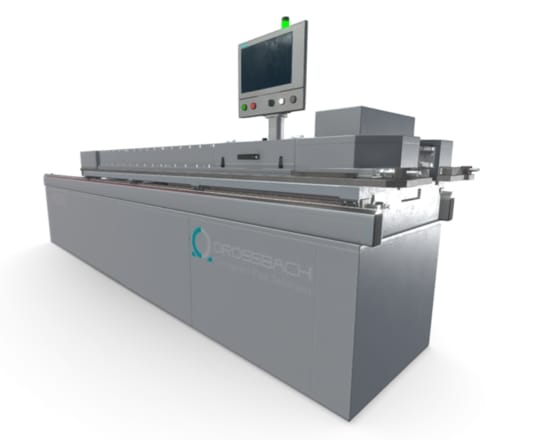

“Right-hand” and “Left-hand” execution

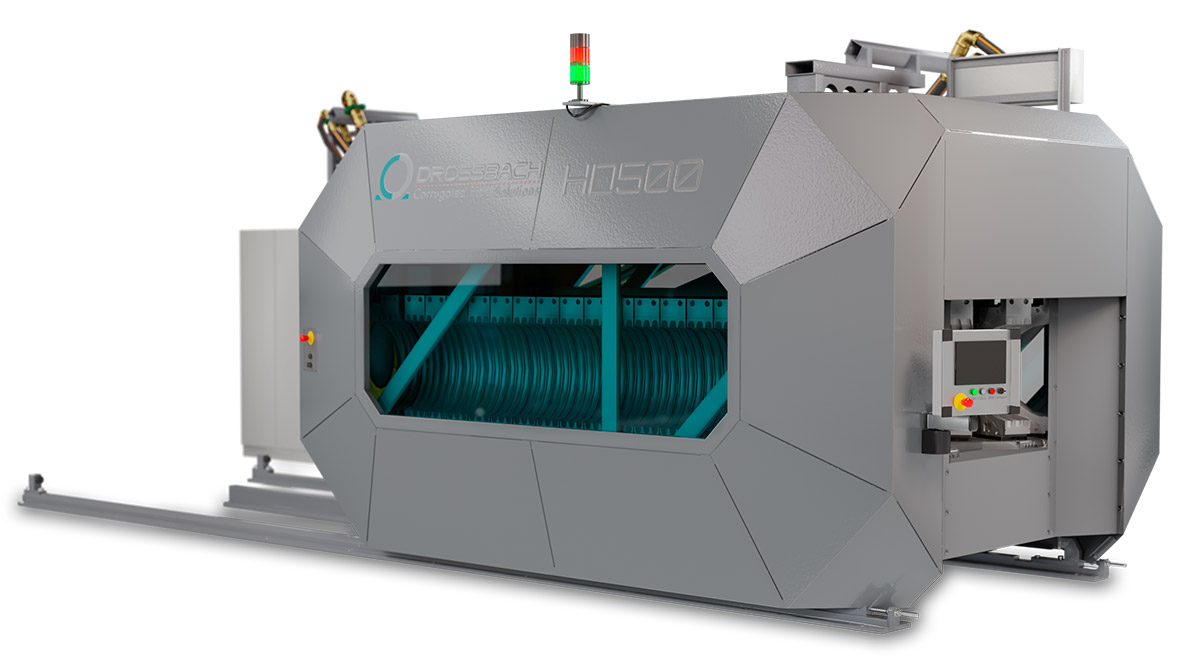

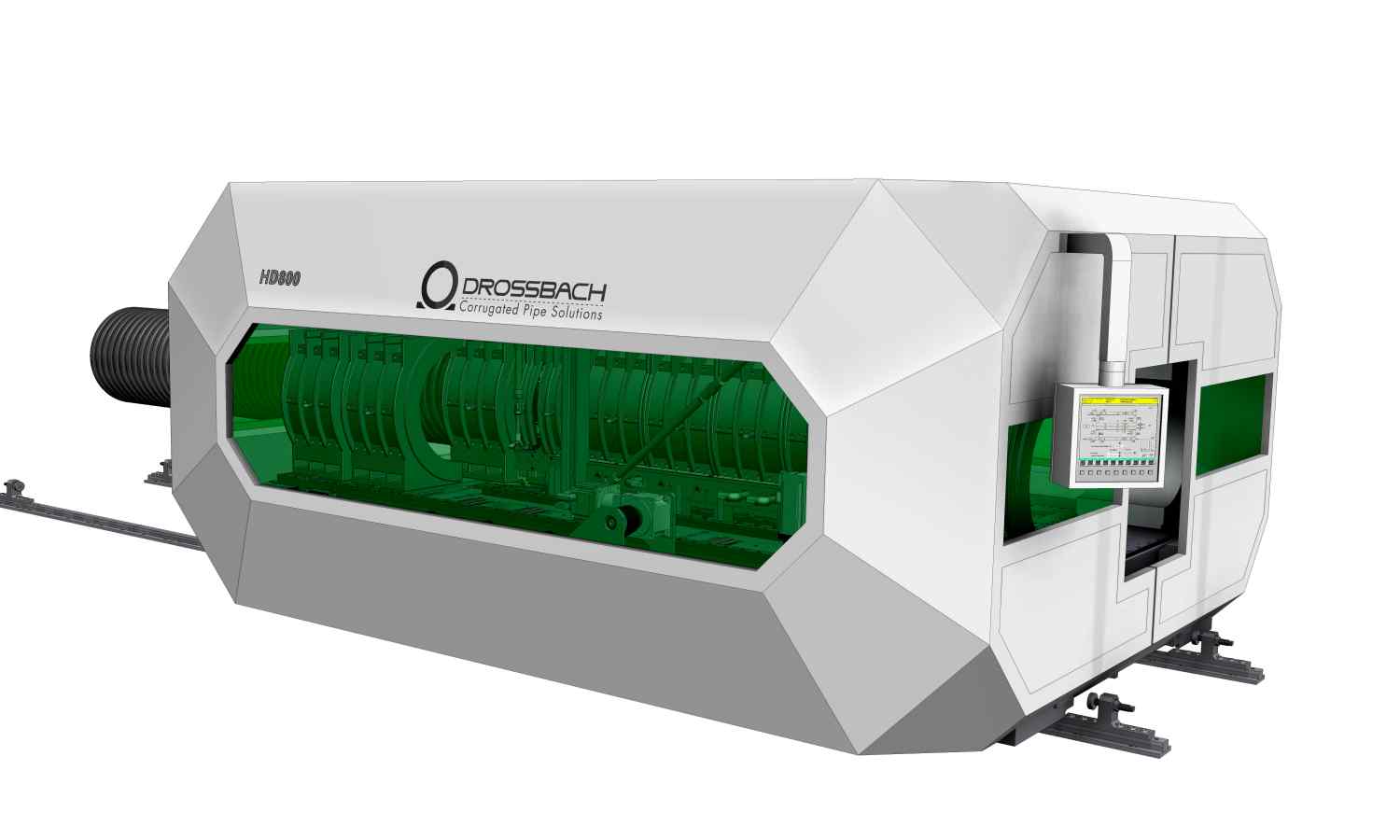

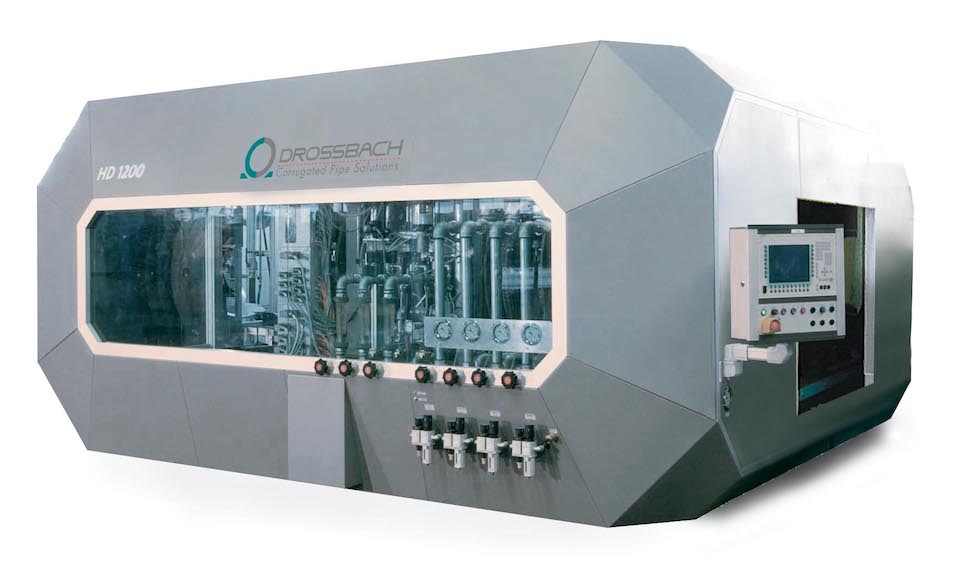

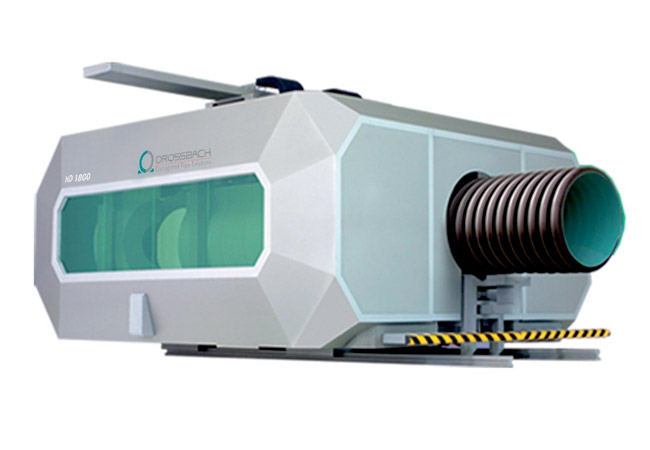

DIAMETERS:

from ID 40 mm to OD 250 mm / 1.5/8" - 12"

Materials:

PE, PP, PA, ABS, PBT, PC, etc.