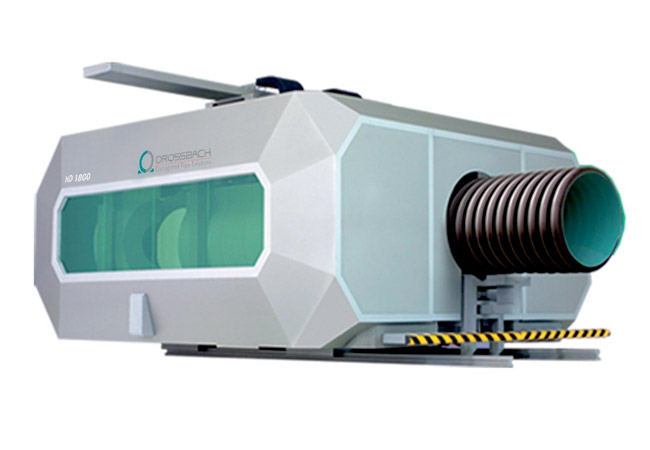

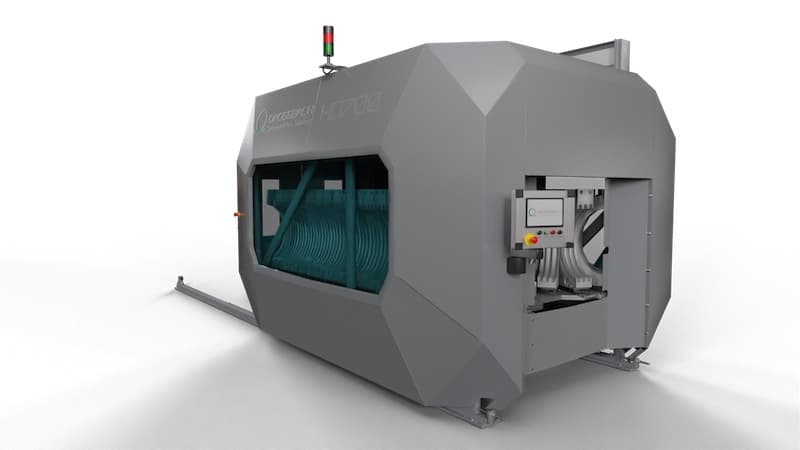

- Simple and fast exchange of mold block inserts.

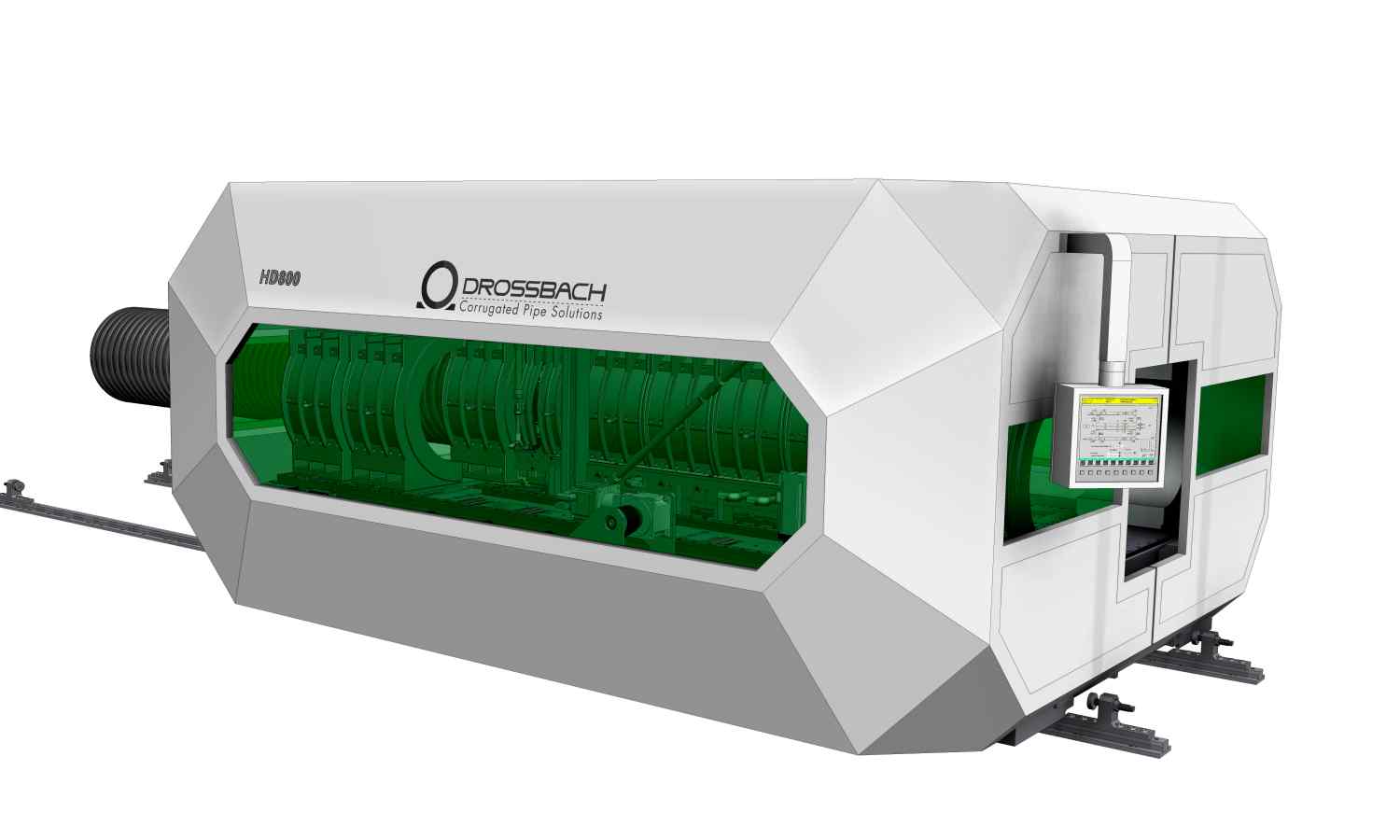

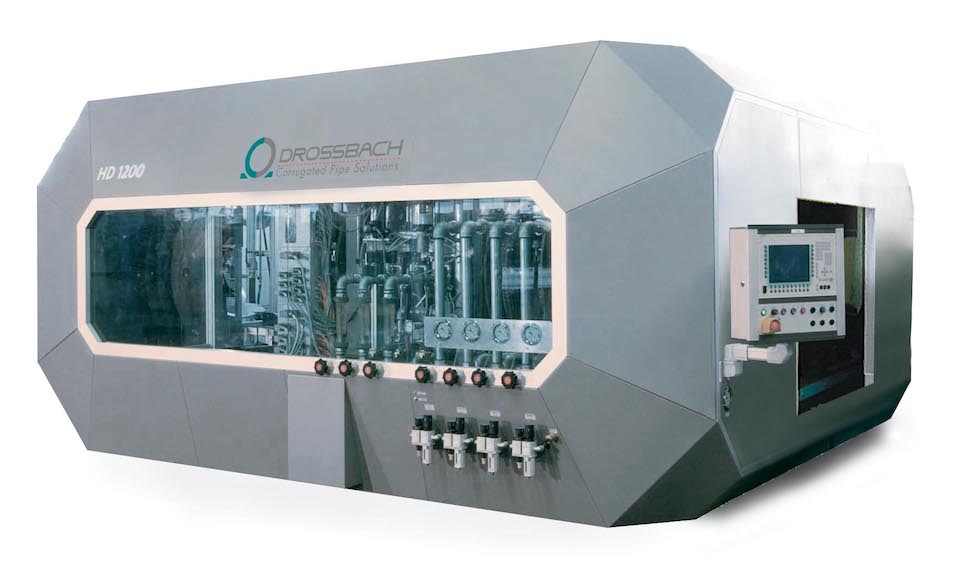

- The complete diameter tools from ID 150 to ID 400 (6" - 16") are compatible with the HD 800 and the HD 1200.

DIAMETERS:

from ID 100 mm to OD 560 mm / 4" - 22"

Materials:

PE, PP, PVC, further plastics available upon request.