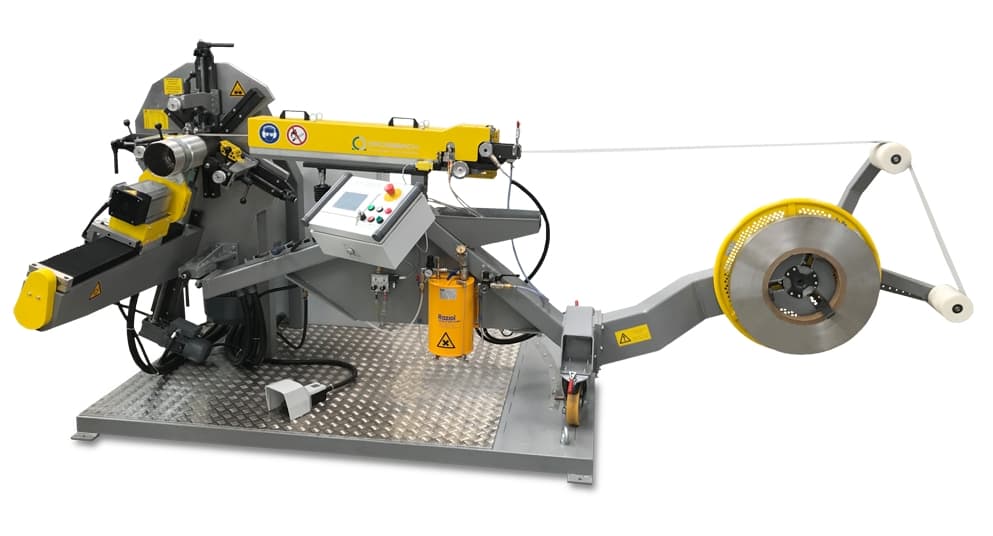

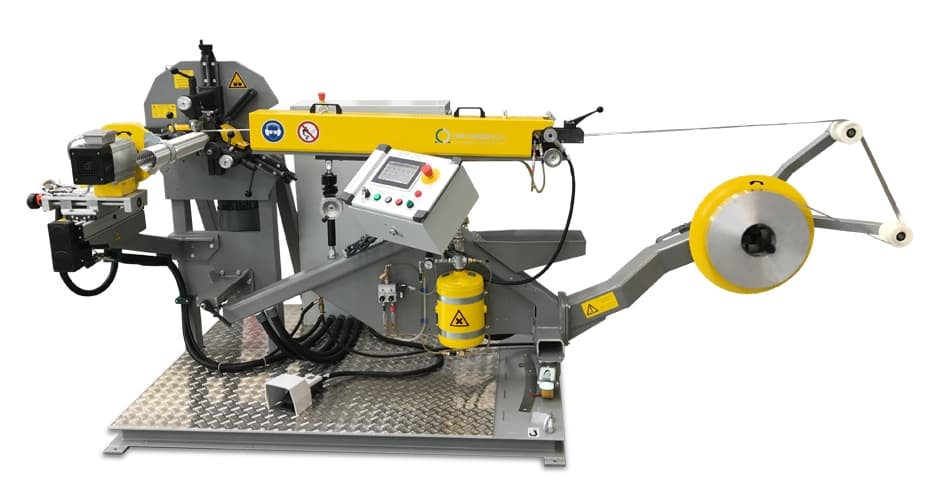

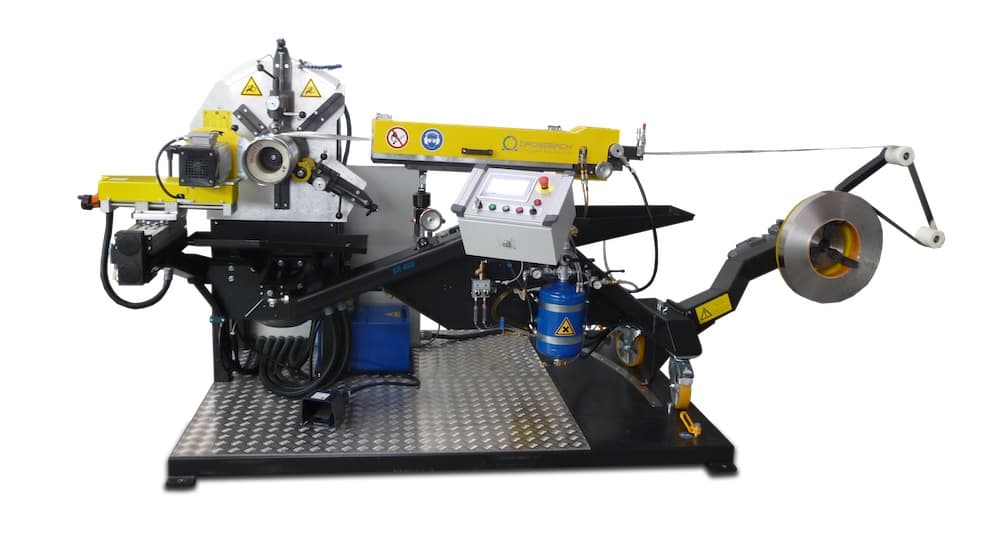

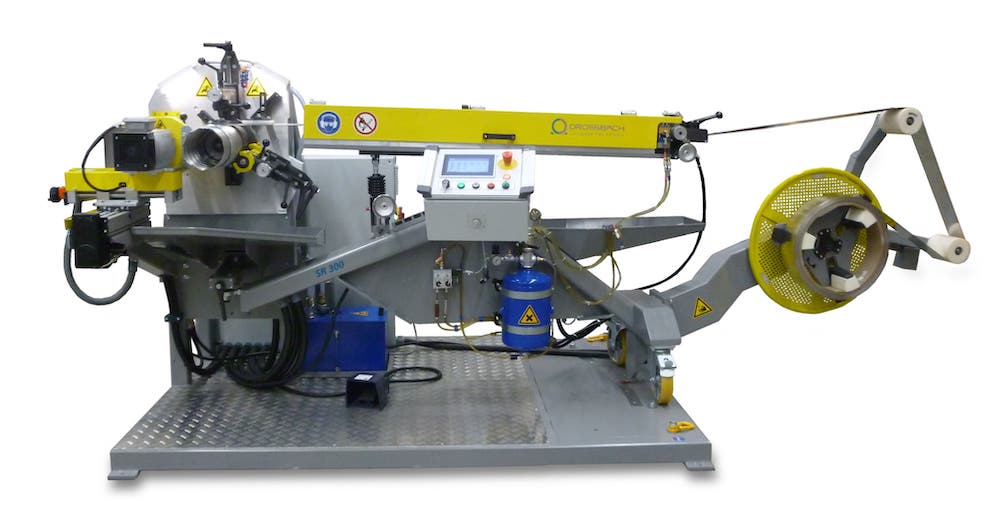

Drossbach SPF COMPACT

The most economic way to produce chimney liners

Technical Data

| Max. strip speed | 65 m/min / 213 ft./min |

| Max. pipe diameter | 200 mm / 8" |

| Strip thickness: | |

| - Aluminium or stainless steel | up to 0,18 mm / .007" |

| Max. strip width | 54 mm / 2.126" |

| Max. pipe length | 100 m / 328 ft. |

| Min. pipe length | 0,30 m / 1 foot |

| Electrical power | 7 kW |

| Compressed air supply | 6,0 bar |

| Weight | 800 kg / 1,764 lbs |

Characteristics

Documentation

- Most economic basic spiral pipe machine to produce flexible chimney flue liners from 50 to 200 mm (2" to 8"). Double wall or single wall liners possible.

- Machine is downsized as much as possible but including all typical DROSSBACH features.

- Easiest adjustments and recreation of production settings, with a multitude of scales.

- All necessary parts are integrated in one machine frame, strip guide, profiling unit, automatic strip lubrication, pipe winding and closing system.

- Optional flying automatic saw offers constant running pipe production.

- Optional manual material decoiler with adjustable core and strip break.

- Diameter changeover possible in less than 10 minutes for highest flexibility and lowest storage effort.

- Automatic strip lubrication for highest efficiency.

- All pipe designs are made of one single strip.

- Well-lit working station

- All diameter tools and profiling equipments can be interchanged with SPF 250.

DIAMETERS:

from 50 mm to 200 mm / 2" - 8"

depending on pipe profile

Materials:

Aluminium or stainless steel

Application

Flexible chimney liners

acc. to EN 1856, tightness class P1, double wall, inside smooth

Flexible chimney liners

acc. to EN 1856, tightness class P1, single wall

Metal Pipe Machines

Other equipment in this category

Create an order request

+