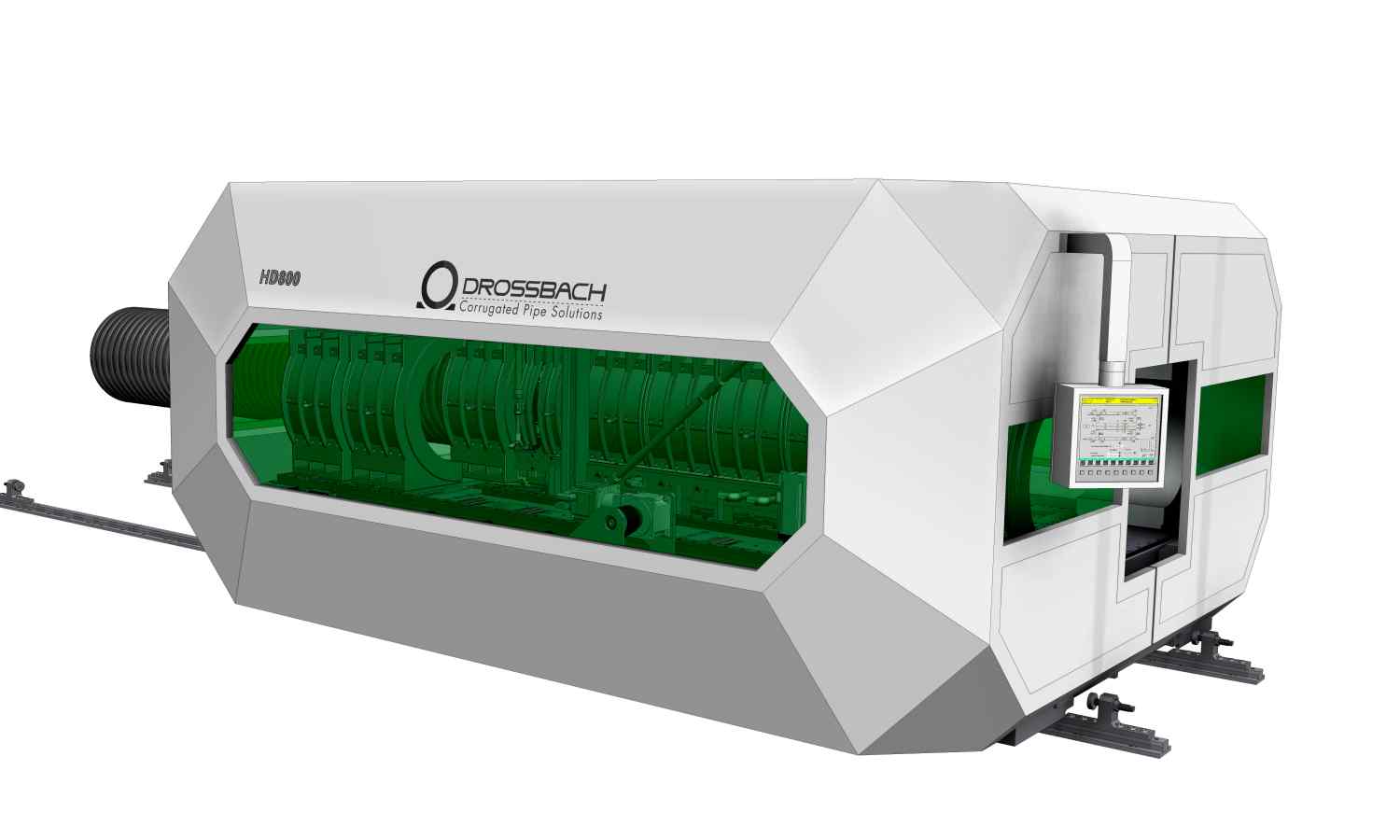

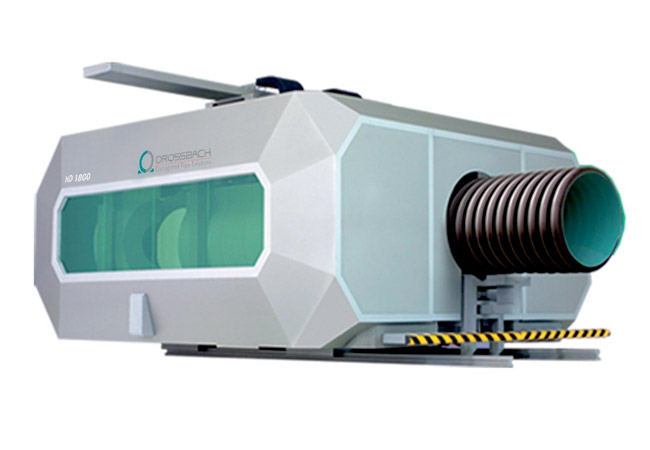

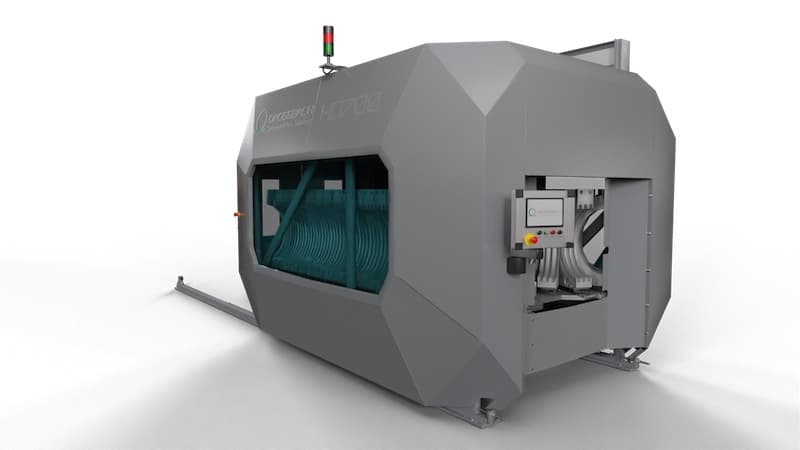

- The spiral-mandrel die head cares for a constant quality of the corrugated pipe with a consistent even wall distribution.

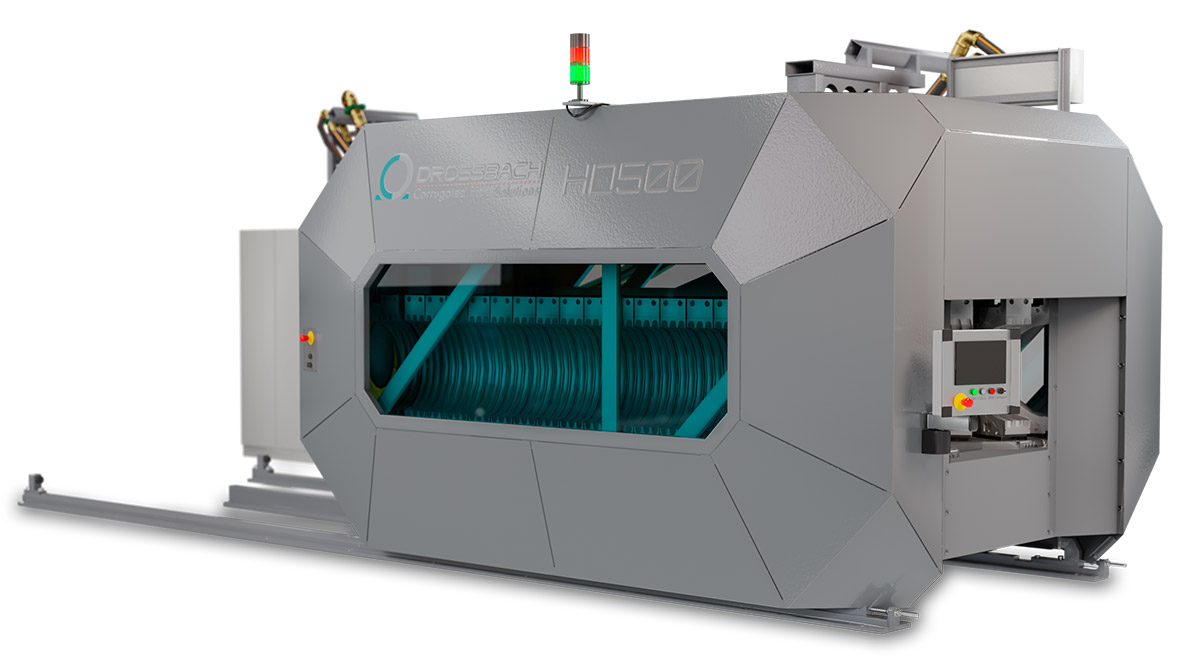

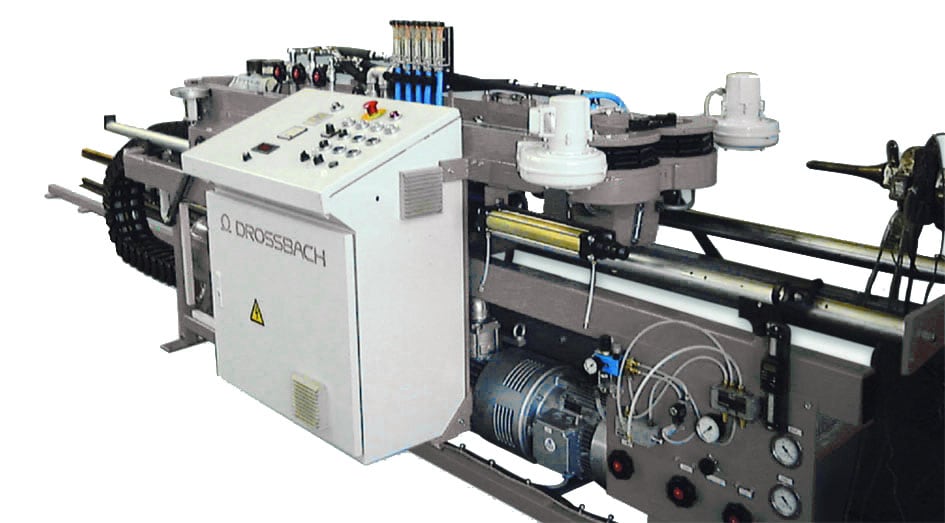

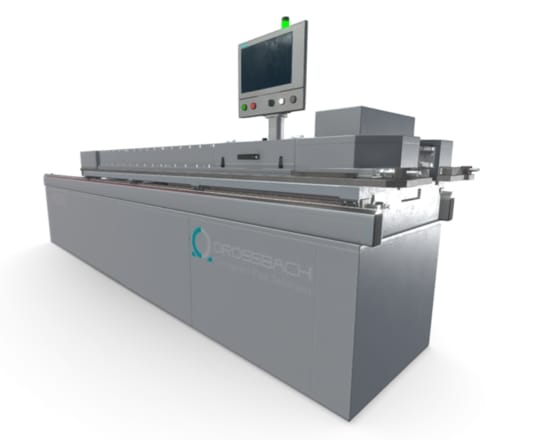

- Computer-controlled operation and monitoring of the complete production process; remote control and servicing available.

DIAMETERS:

from ID 150 mm to OD 1.200 mm / 6" - 48"

Materials:

PE, PP, PVC, further plastics available upon request.