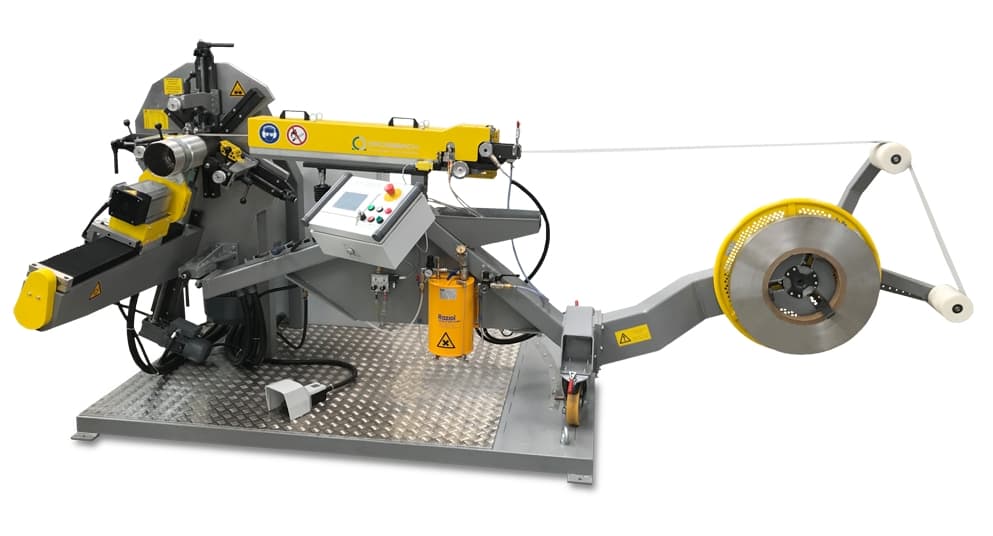

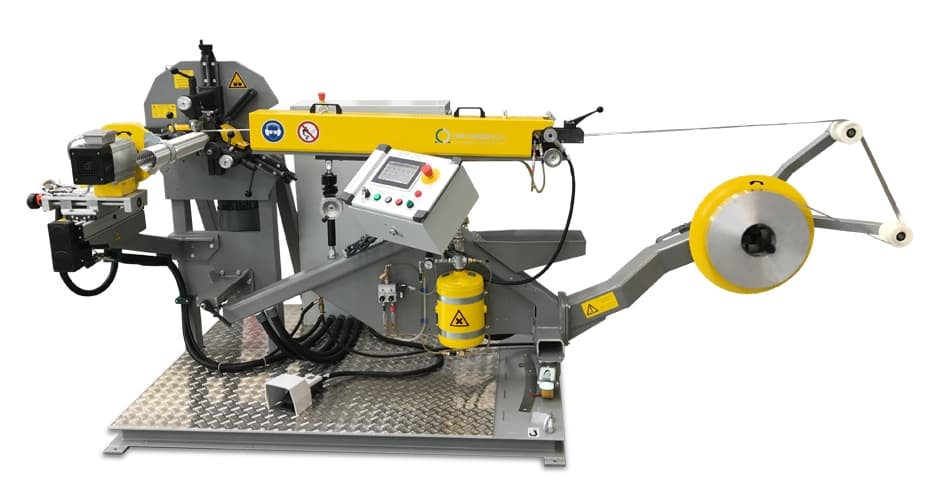

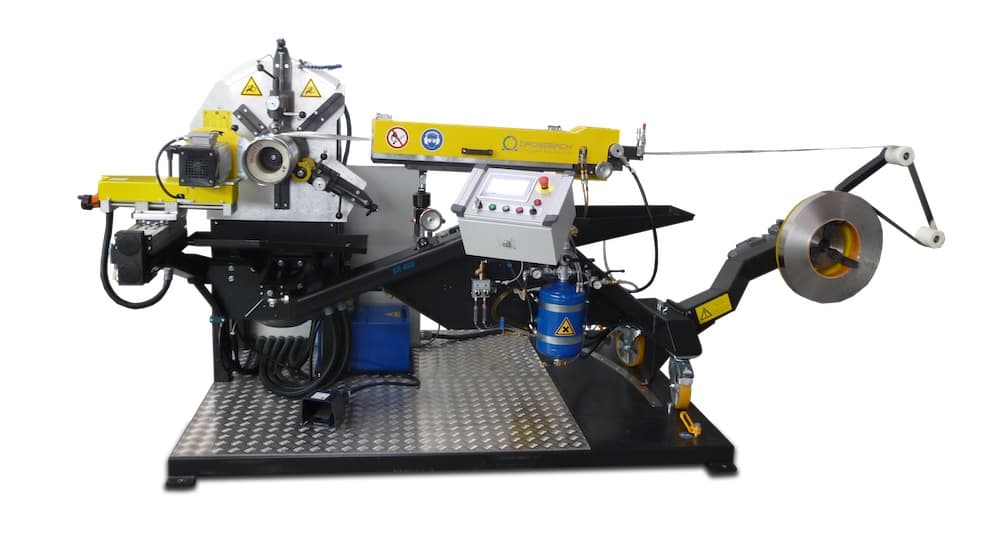

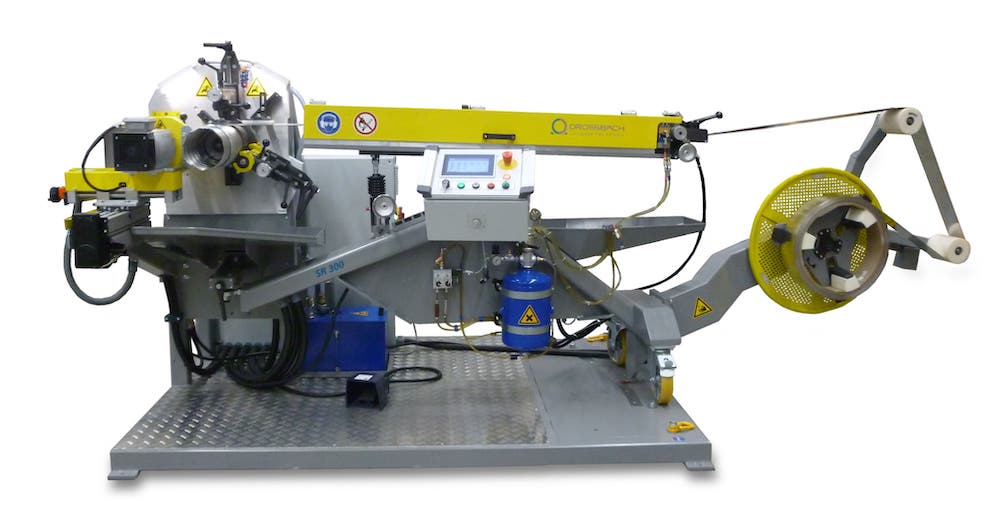

Drossbach SR 200-T2

Unbreakable reliability for endless production

Technical Data

| Max. strip speed | 70 m/min / 230 ft./min |

| Max. pipe diameter | 210 mm / 8.1/4" |

| Strip thickness: | |

| - steel, galvanised or stainless | up to 0,6 mm /.024" |

| Max. strip width | 78 mm / 3.071" |

| Max. pipe length | 150 m / 492 ft. |

| Min. pipe length | 0,30 m / 1 foot |

| Electrical power | 14,1 kW |

| Compressed air supply | 6,0 bar |

| Weight | 1.200 kg / 2,646 lbs |

Characteristics

Video

Documentation

3d-Modell

3d-Modell

- Famous long-life machine with world-wide reputation to produce post-tensioning pipe from 25 to 210 mm / 1" to 8.1/4". Now as upgrade to the well-known bestseller.

- All important parts integrated in one machine frame, strip guide, profiling unit, automatic saw.

- Easiest adjustments and recreation of production settings, with a multitude of scales.

- Variety of sheathing can be produced with three different standard pipe profile designs. Various special pipe profiles can be designed.

- High torque and performance for heavy duty pipe up to 0,6 mm / .024" strip thickness.

- Flying automatic saw for pipe cut durng production.

- Short-length sheathing connectors can be produced inline.

- Strip lubrication by coolant water for highest efficiency.

- Spot-welder available to join strip ends, plug-in possible into control board of the SR 200-T2:

- Well-lit working station

- 2 sizes of Ovalizers available to flatten the sheathing into 70 x 21 mm and 85 x 21 mm including the matching couplers.

DIAMETERS:

from 30 mm to 210 mm / 1.1/5" - 8.1/4"

Materials:

Mild, galvanized and stainless steel or other specific materials.

Application

Post-tensioning pipe

and connectors acc. to EN 523 und EN 524

Heavy flex and heavy flex hybrid pipe

for exhaust and chimneys

Metal Pipe Machines

Other equipment in this category

Create an order request

+