Company

Expired

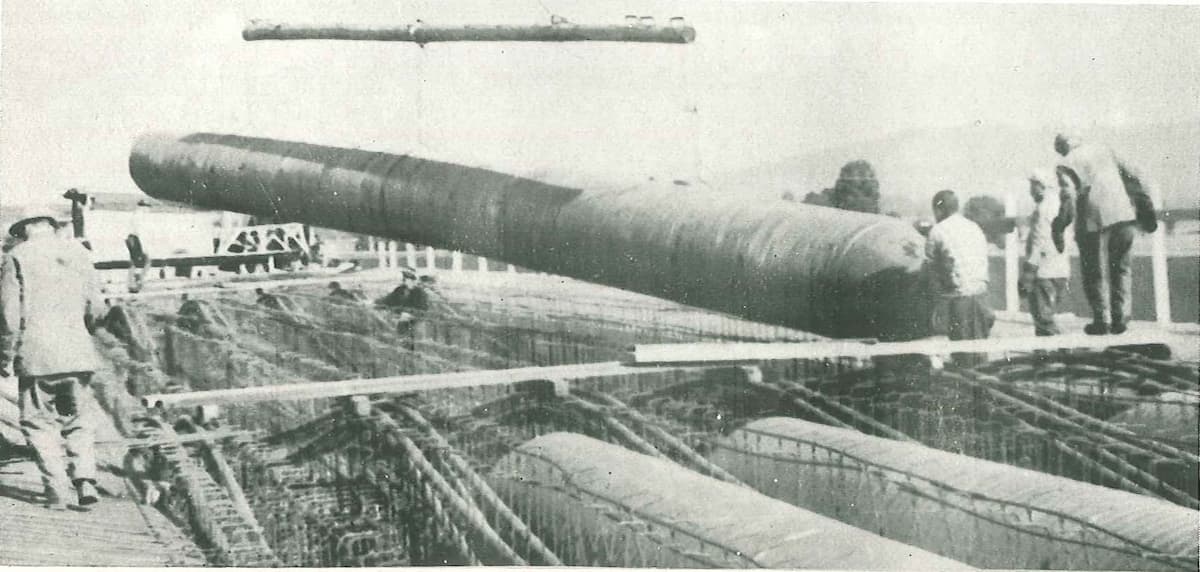

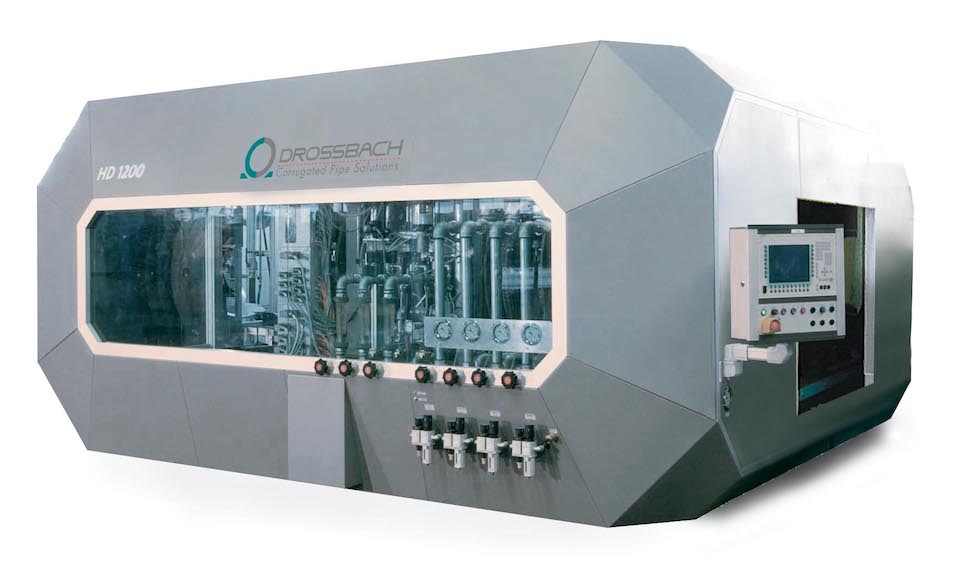

Since 1919, DROSSBACH has focused on the development of lightweight, long-lasting pipes and efficient production technology. For our customers, we are a universal provider of ready-made solutions.

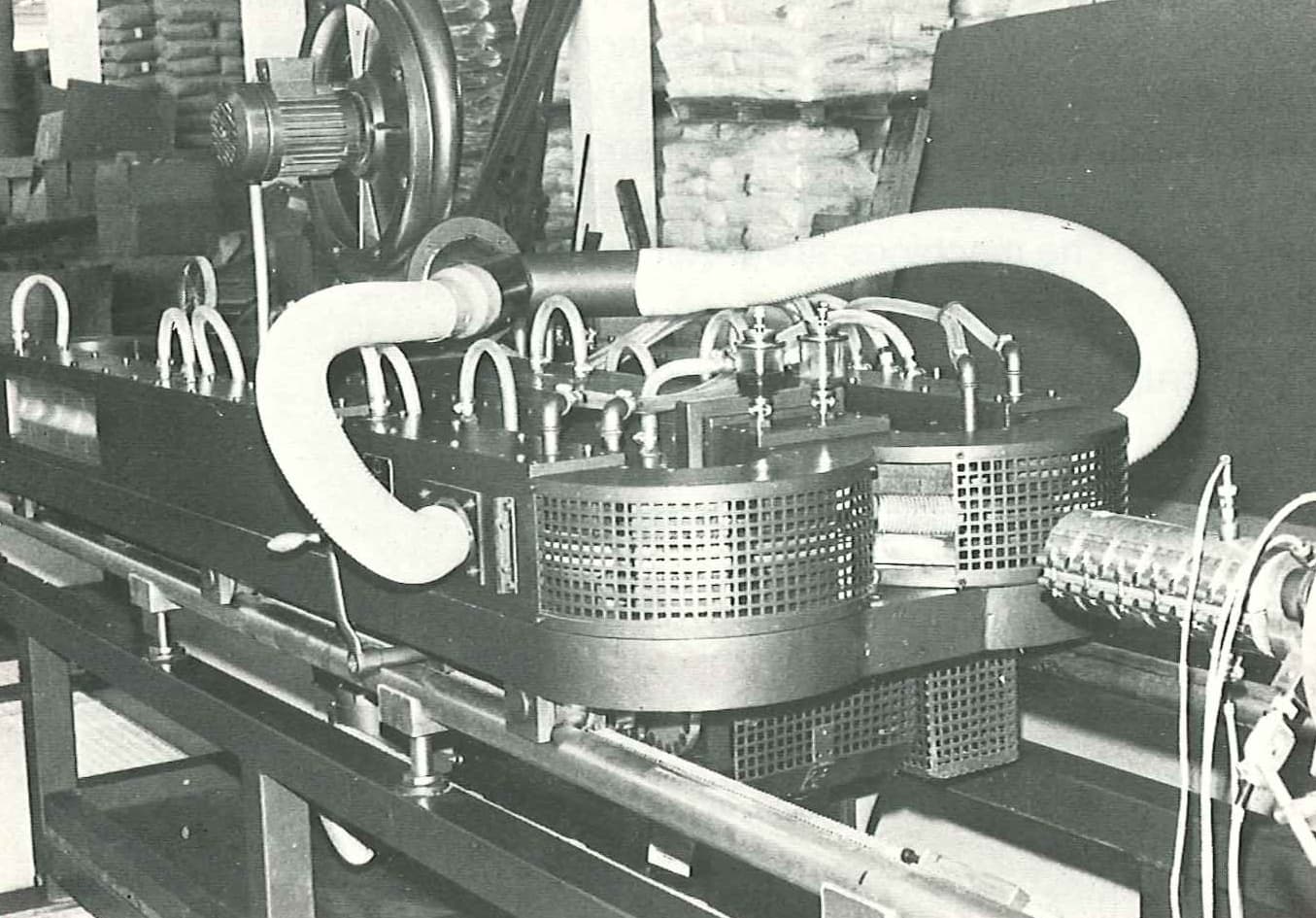

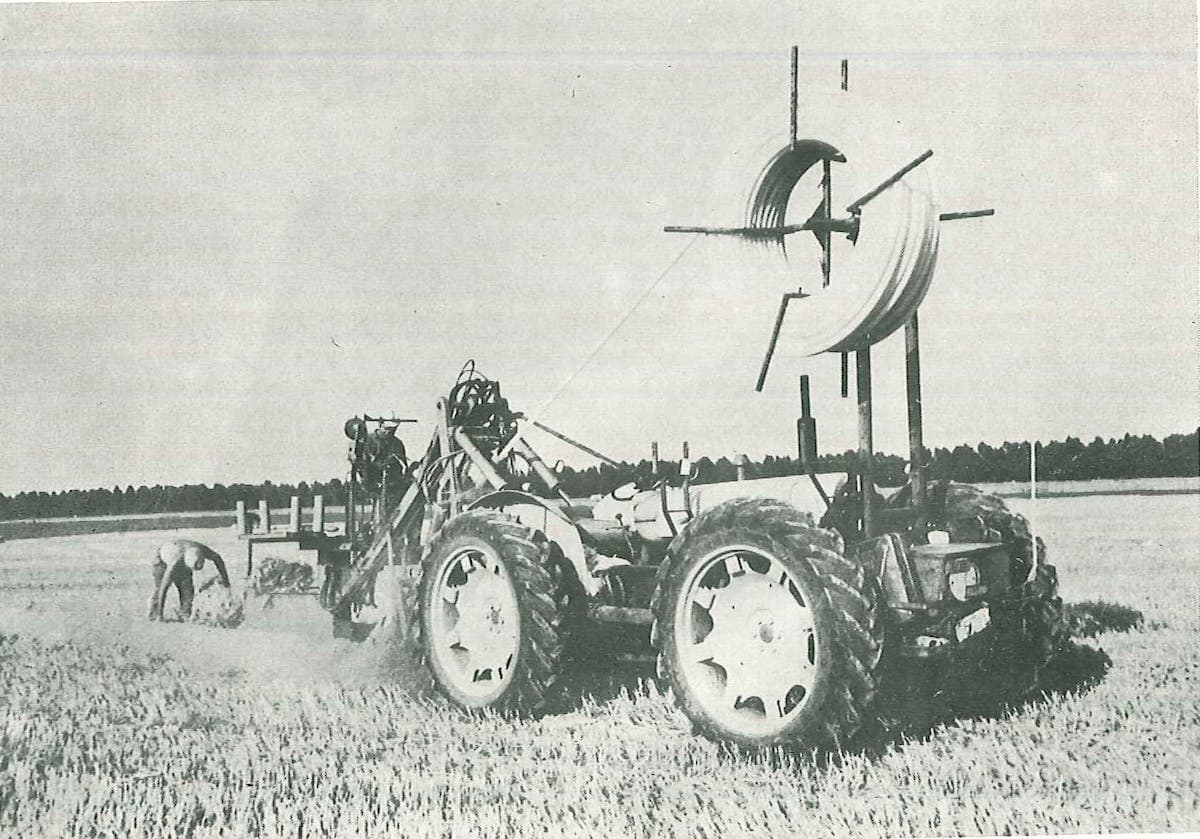

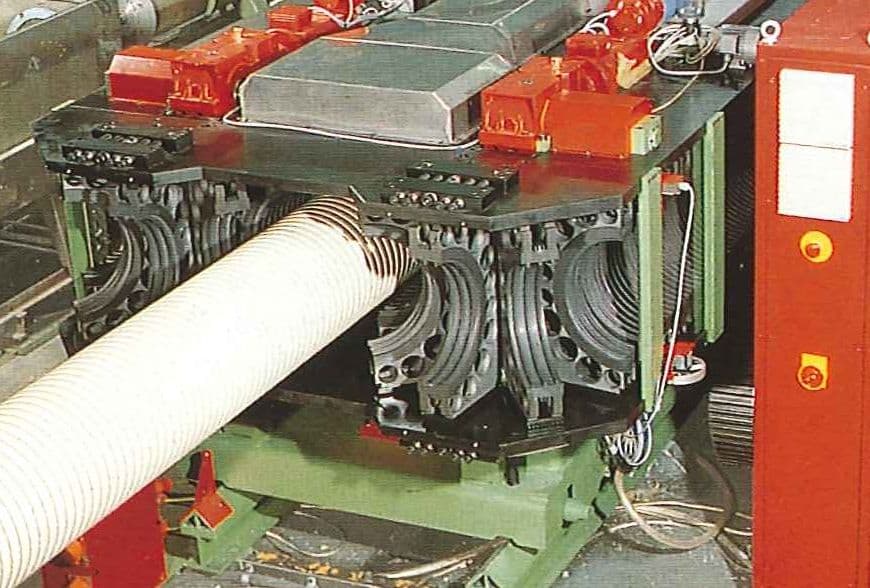

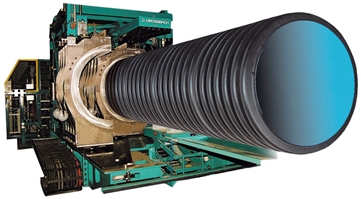

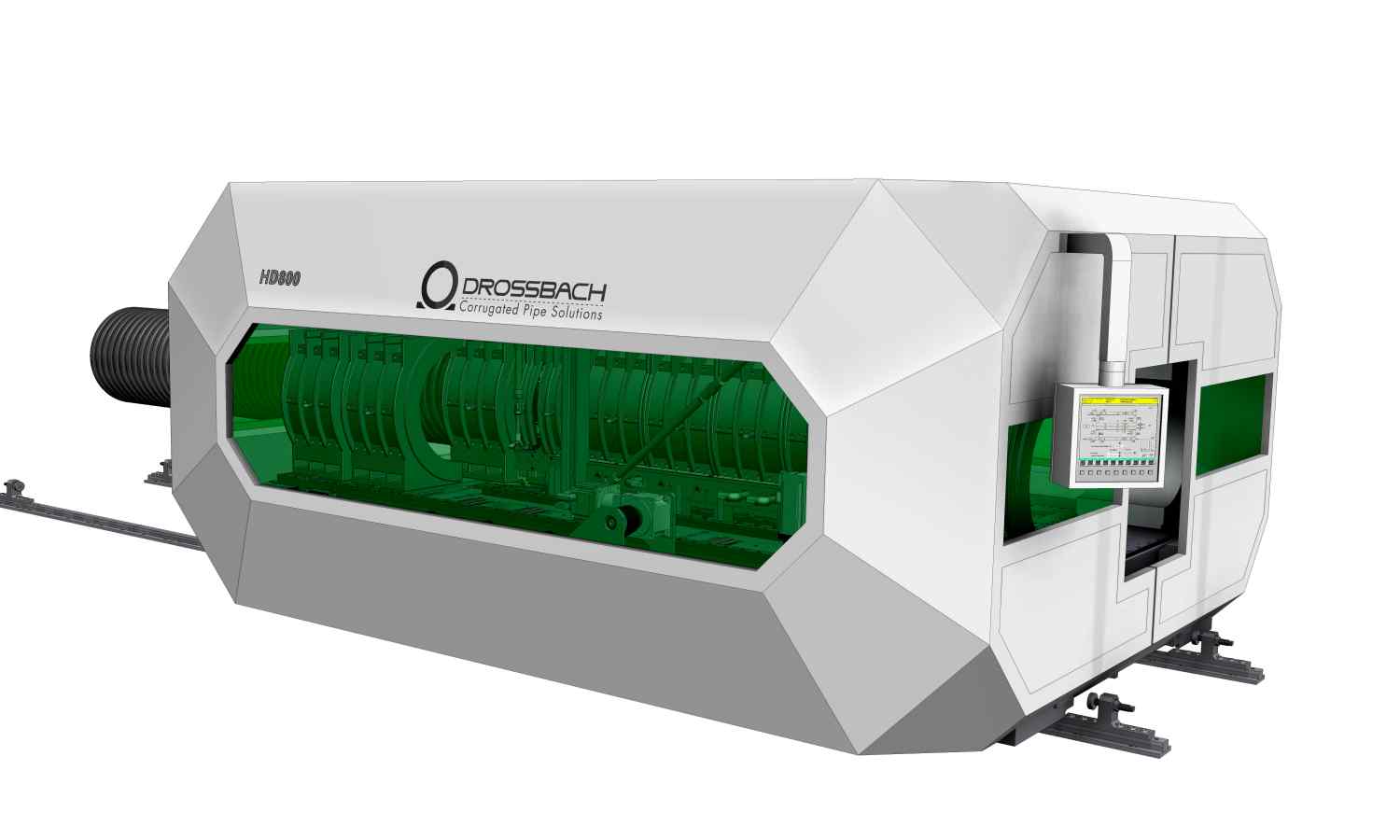

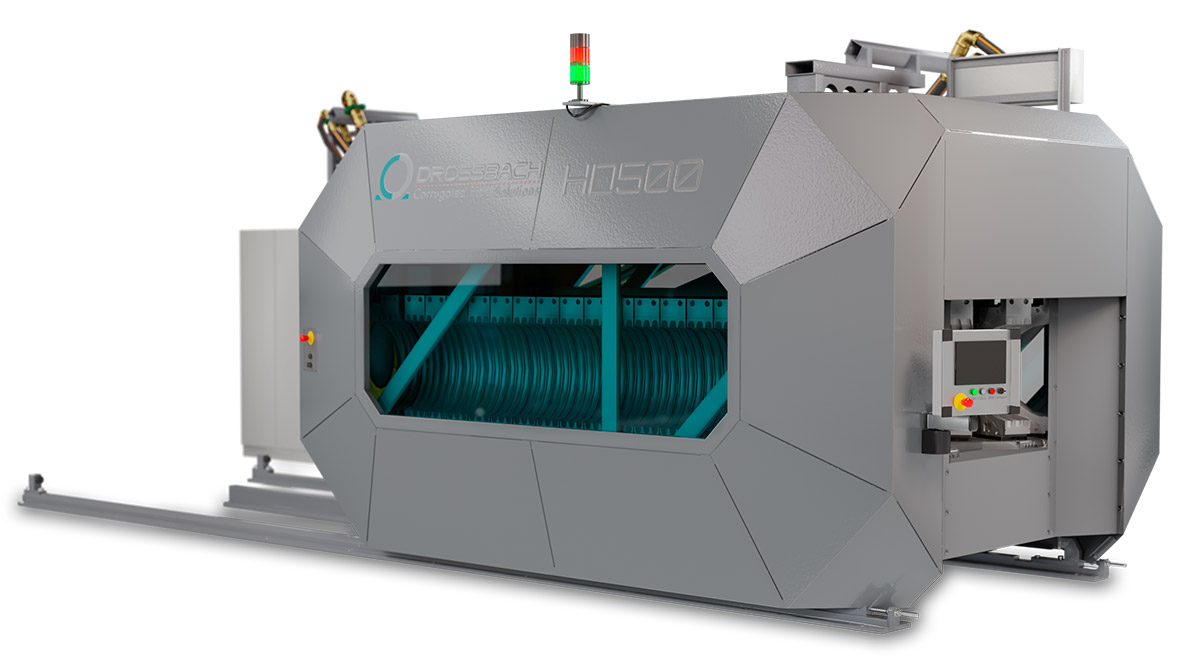

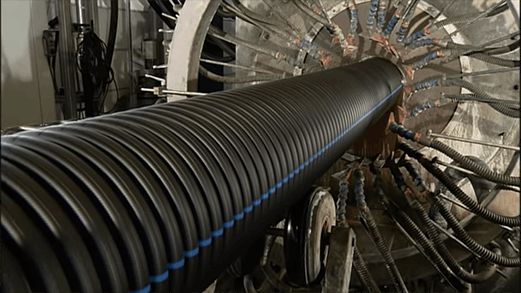

- High-performance, innovative equipment for the economical production of corrugated plastic and spiral metal pipes.

- Consulting and services for business development, production organisation and optimisation of production processes.

- Service and support to ensure long service life of the equipment and increase the profitability of the business.

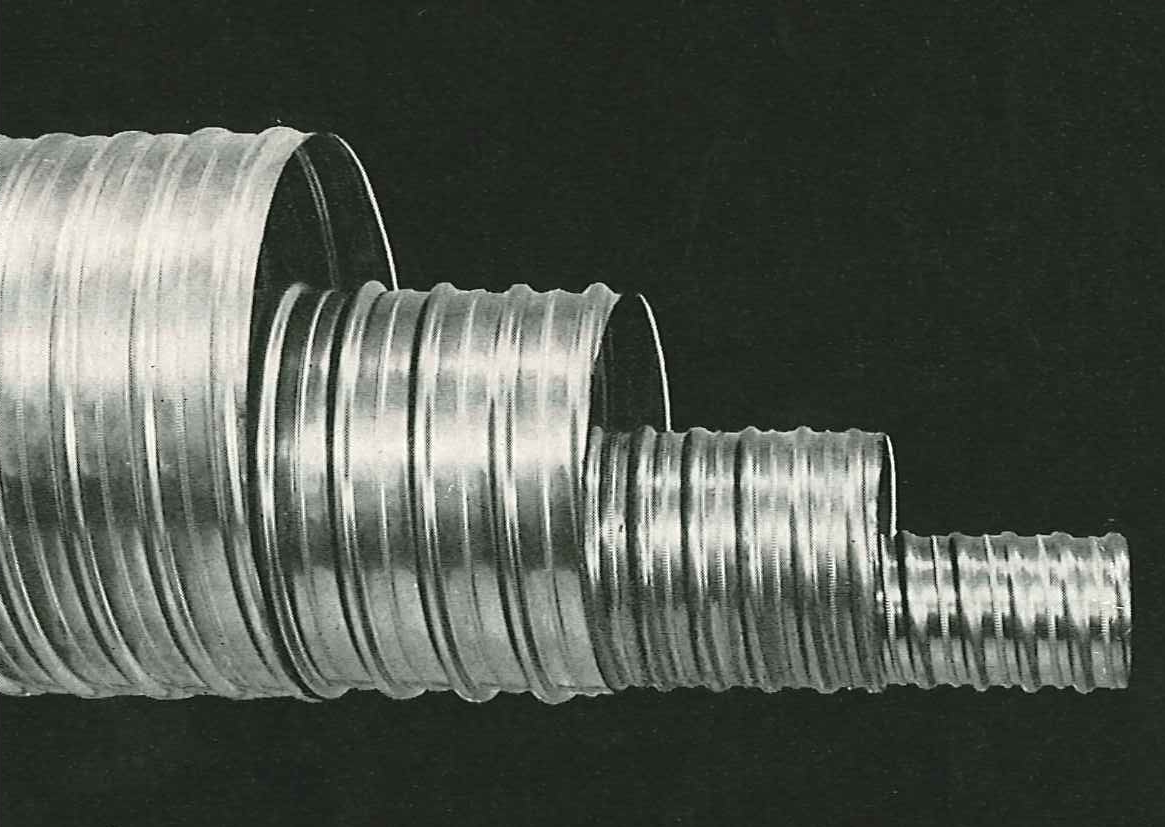

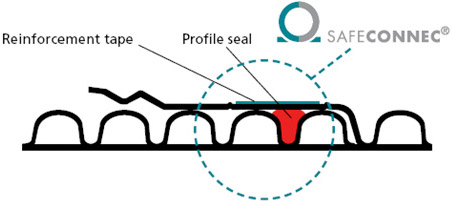

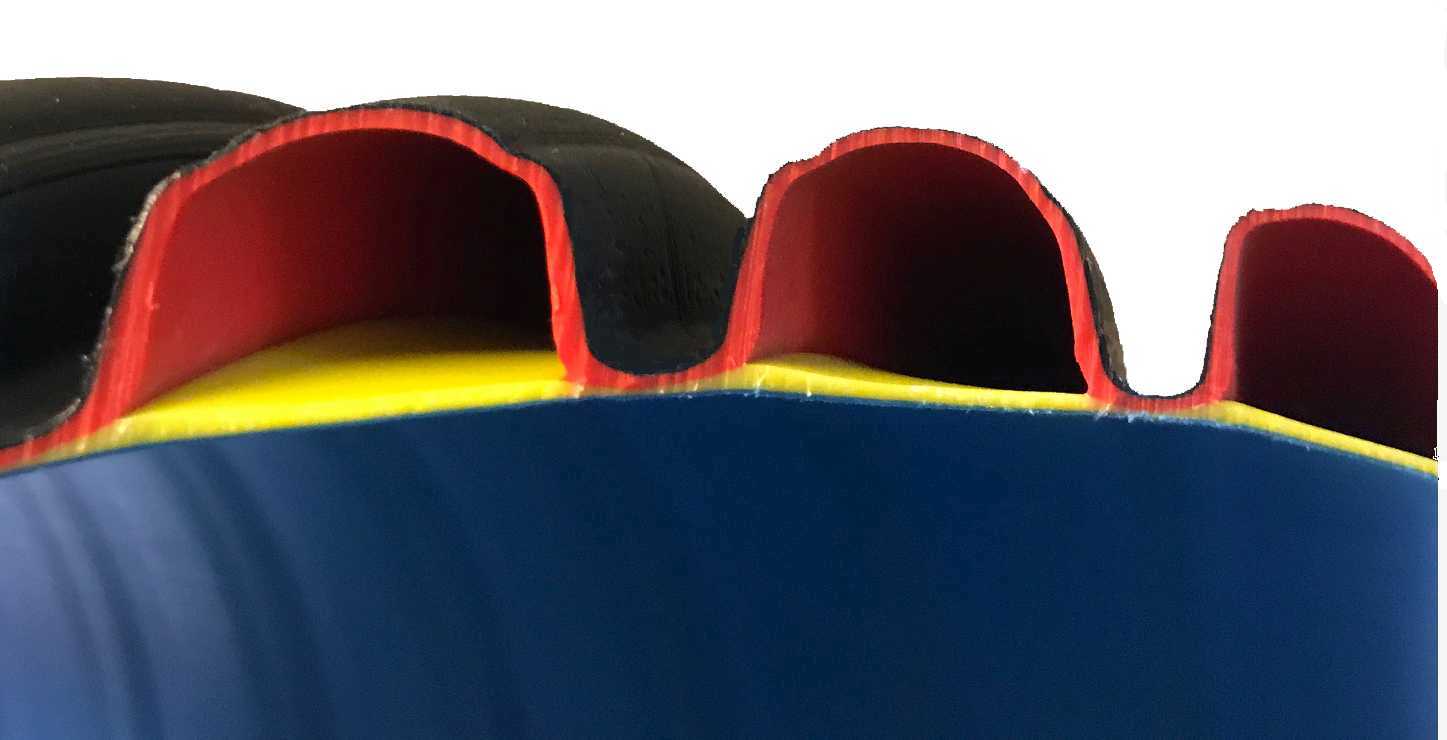

- Innovative design of the pipe profile in accordance with customer requirements and market requirements.

- We advise market leaders and newcomers

- We create equipment for your success

- We will never leave you without support

We share our know-how and experience with customers and partners, providing a holistic business concept called Corrugated Pipe Solutions - CPS

Upgrade your business with DROSSBACH and Corrugated Pipe Solutions!

Experience that serves you

Because of a wealth of experience in high-quality corrugated plastic pipe machinery, outstanding metal pipe machinery and extensive pipe business services, DROSSBACH and its partners offer customer-orientated solutions. Furthermore, close contacts with long-term partners promote DROSSBACH's excellent reputation worldwide.

Since end of 2012 DROSSBACH Maschinenbau GmbH, M.D.S. Meyer GmbH and WPS - Water Pipe system GmbH are part of one group of companies. This provides synergies that benefits our customers throughout the entire value added process. From design through installation and operations, we are your partner. Our synergies give expertise in all facets of corrugated plastic pipe business, starting with design through manufacturing and commissioning the corrugators including lifetime service by DROSSBACH. For development, design and the choice of the ideal sealing system M.D.S. is your partner and finally the production and supply of corrugated pipe and fitting systems by WPS.

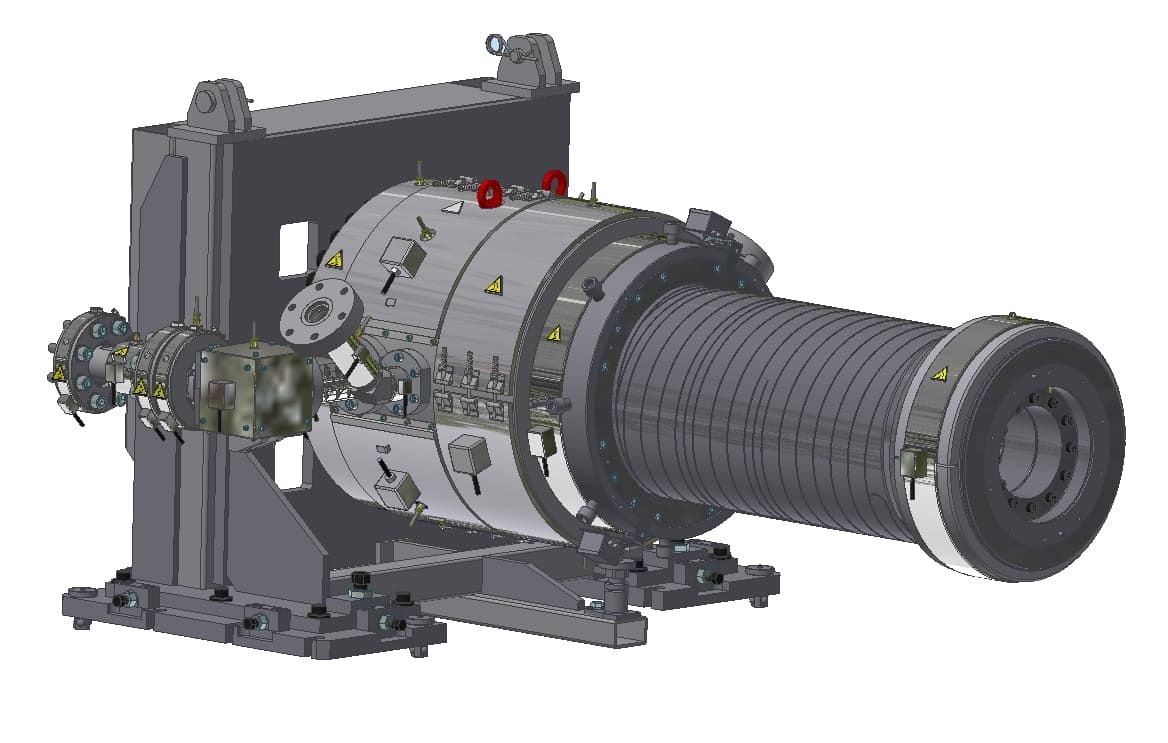

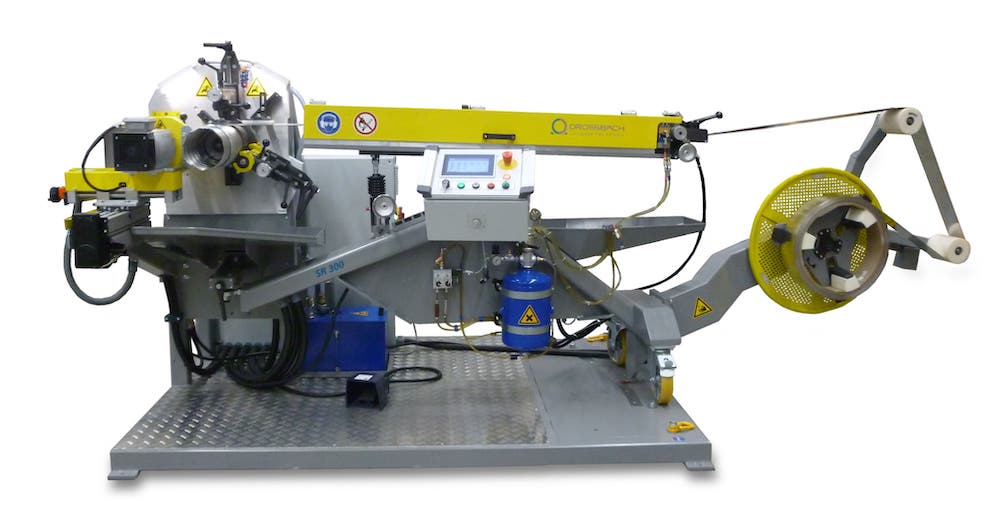

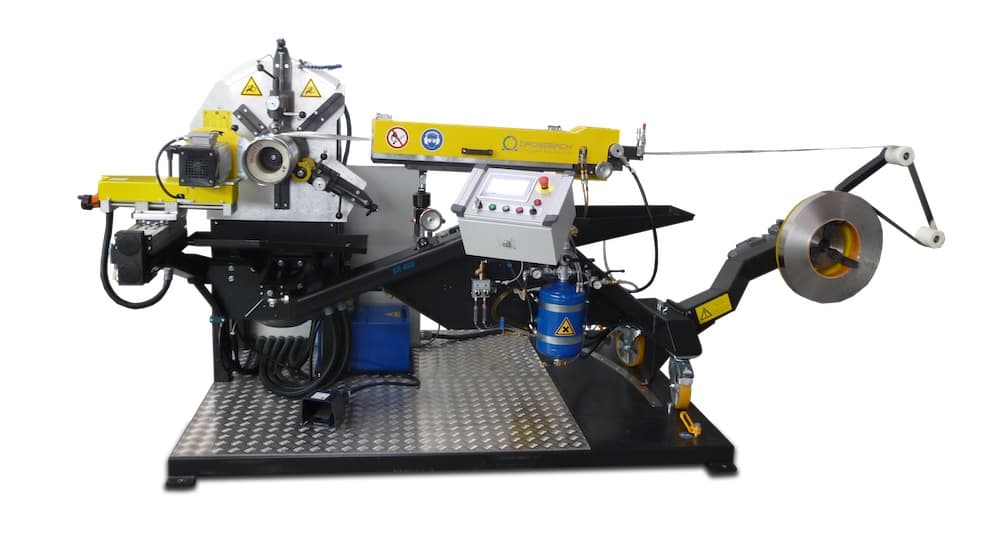

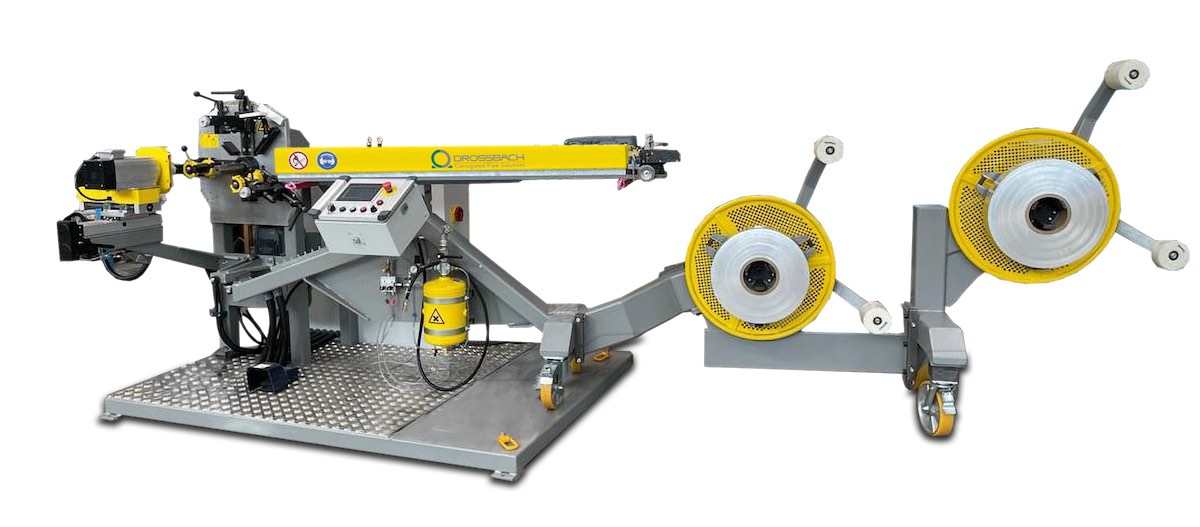

Since six decades DROSSBACH is the embodiment for metal pipe machinery and sets the benchmark for flexible and state-of-the-art metal pipe production. Most pipe profile designs are produced from one metal strip, a USB connection enables production data download for efficiency analysis, the production is fully computerized and programmable.

Furthermore the tools and profiling equipment can be interchanged between the machines. Experience, accuracy, competence and passionate pursuit of quality, enable DROSSBACH to develop high-class, efficient and reliable machines - Quality without compromise.