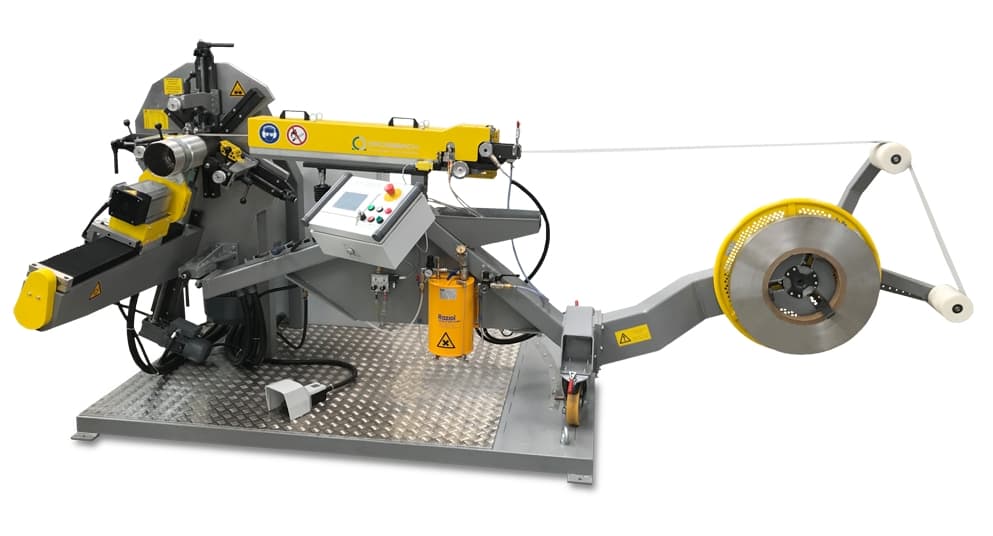

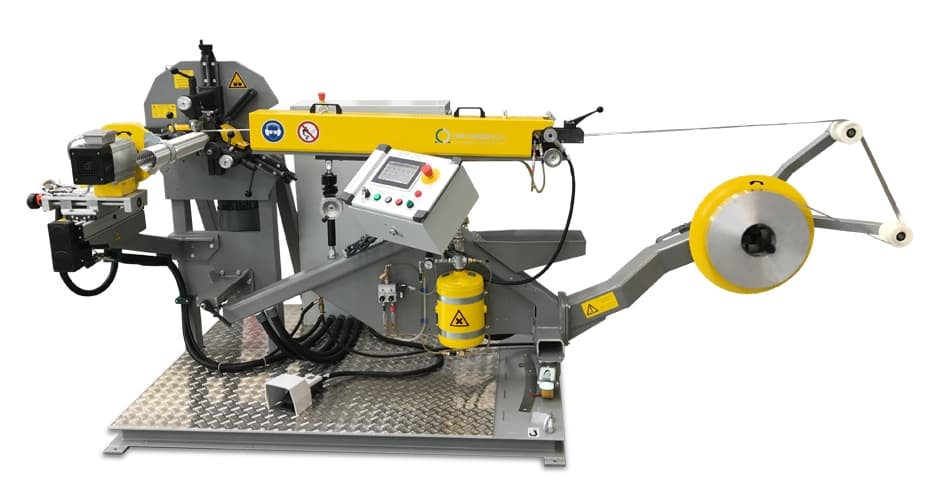

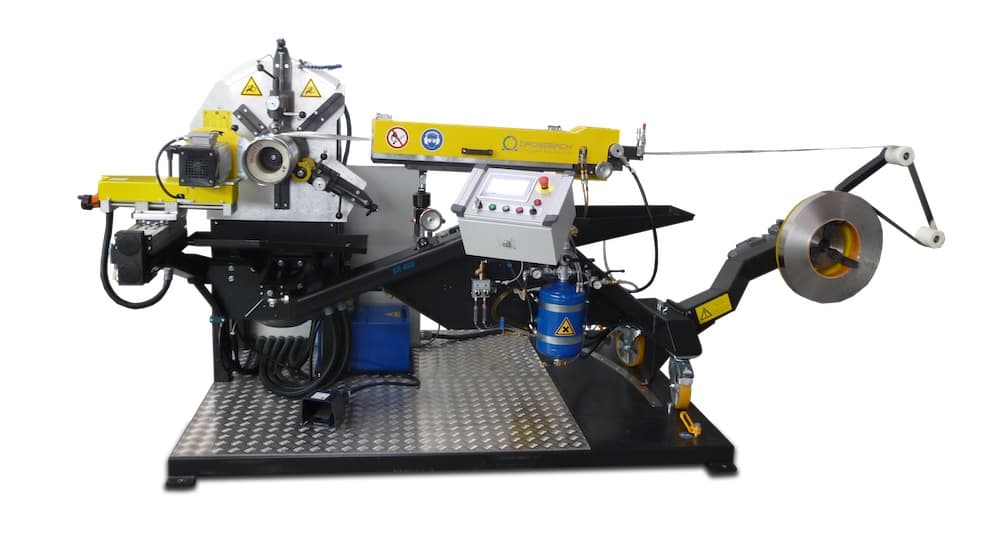

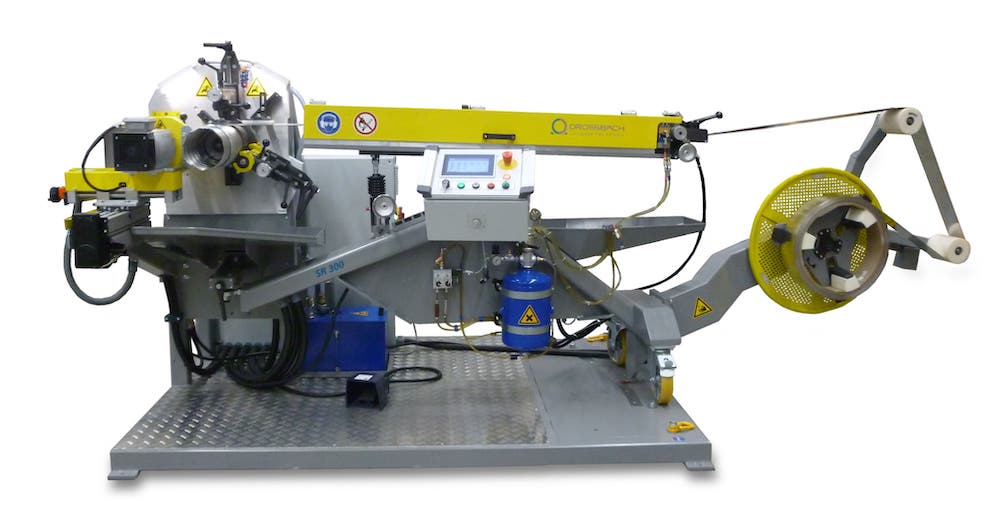

DROSSBACH SR 300

Highest flexibility with a machine for all purpose

Technical Data

| Max. strip speed | 75 m/min / 246 ft./min |

| Max. pipe diamter | 300 mm / 12" |

| Strip thickness: | |

| - steel, galvanised or stainless | up to 0,6 mm/.024" |

| - aluminum | up to 0,18 mm/.007" |

| Max. strip width (depending on profile design) |

up to 78 mm/3.071" |

| Max. pipe length | 200 m / 656 ft. |

| Min. pipe length | 0,50 m / 1.6 ft. |

| Electrical power | 19,5 kW |

| Compressed air supply | 6,0 bar |

| Weight | 1.200 kg / 2,646 lbs |

Characteristics

Video

Documentation

3d-Modell

3d-Modell

- Versatile machine to produce post tensioning pipe and heavy flex exhaust pipe.

- Second lubrication system can easily installed with a plug-and-play connection for the production of flexible single and double wall chimney liners and ventilation ducts.

- Central operator panel with touch screen for easy control.

- Synchronized drivers enable strip speeds up to 75 m/min / 246 ft./min.

- Adjustable core of uncoiler for flexible material purchase.

- Integrated automatic cutter allows permanent production without stop.

- Various pipe designs can be produced by means of different tools at minimum changeover possible in less than 10 minutes for highest flexibility and lowest storage effort.

- All pipe designs are made of one single strip.

- Full computerized and programmable production.

- USB connection at the operation panel allows periodical analysis of the production data.

- Integrated modem for trouble shooting, software updates or language uploads.

- Computerized and programmable handling of orders and production batches.

- Most diameter tools and profiling equipments can be interchanged between SPF 450 S and SPF 250.

- Plug-and-play connection to optional compressing unit and printer.

- Well-lit working station

- Diameters up to 300 mm (12"), depending on pipe design.

DIAMETERS:

from 30 mm to 300 mm / 1.1/5" - 12"

depending on pipe profile

Materials:

Aluminium, stainless steel or other specific materials.

Application

Flexible chimney liners

acc. to EN 1856, tightness class P1

Flexible HVAC ducts

acc. to DIN 24146

Heavy flex and heavy flex hybrid pipe

for exhaust and chimneys

post-tensioning pipe

and connectors acc. to EN 523 und EN 524

Metal Pipe Machines

Other equipment in this category

Create an order request

+